Innovative Industrial Robot Revolutionizing Manufacturing Processes

Introduction:

Industrial robots have become an integral part of modern manufacturing processes, revolutionizing the way products are produced. These advanced machines, equipped with cutting-edge technology, have proven to be highly efficient, precise, and reliable. In this article, we will delve into the world of industrial robotics and explore how they have transformed the manufacturing industry.

Opinion/Thought Piece Style:

The Rise of Industrial Robots:

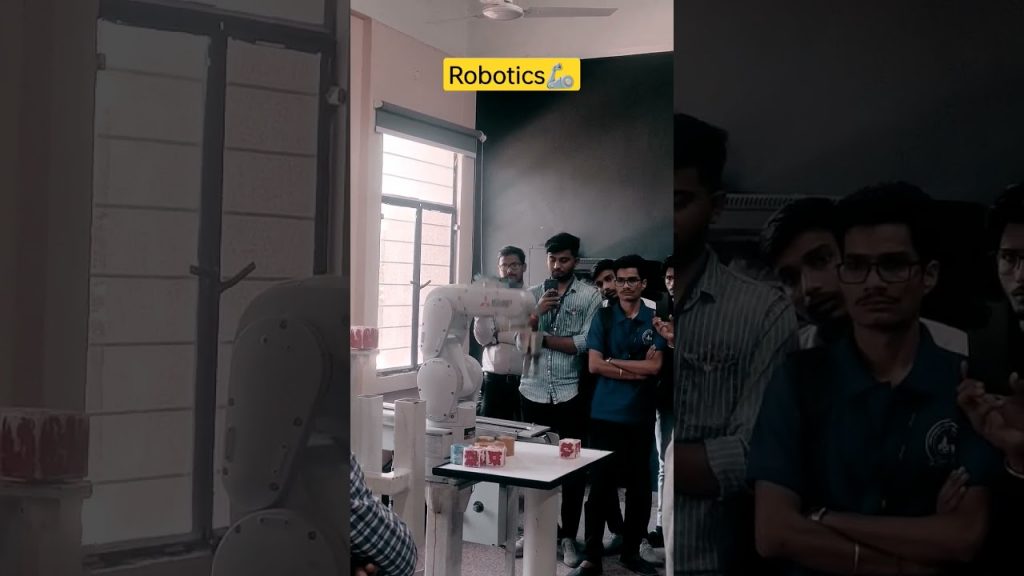

Over the past few decades, industrial robots have gained significant popularity in the manufacturing sector. These robots, also known as robotic arms, are designed to automate various tasks, such as assembly, welding, painting, and packaging. With their ability to work tirelessly, consistently, and with utmost precision, industrial robots have revolutionized the manufacturing industry.

Increased Efficiency and Productivity:

One of the key advantages of using industrial robots is the significant increase in efficiency and productivity. These robots can perform tasks at a much faster pace than human workers, resulting in reduced production time and increased output. Moreover, they can operate continuously without breaks or fatigue, ensuring a consistent level of productivity throughout the manufacturing process.

Enhanced Precision and Quality:

Industrial robots are equipped with advanced sensors and programming capabilities, allowing them to perform tasks with unparalleled precision. This level of accuracy ensures that each product is manufactured to the highest quality standards, minimizing defects and rework. By eliminating human error, industrial robots have greatly improved the overall quality of manufactured goods.

Improved Safety for Workers:

In hazardous manufacturing environments, industrial robots provide a safer alternative to human workers. They can perform tasks in environments with extreme temperatures, toxic substances, or high-risk conditions, eliminating the risk of injury or exposure to harmful elements. By delegating dangerous tasks to robots, companies can prioritize the safety and well-being of their employees.

Cost Savings and ROI:

While the initial investment in industrial robots may seem substantial, they offer long-term cost savings and a high return on investment (ROI). These robots can work continuously without breaks or vacations, reducing labor costs associated with human workers. Additionally, their high precision and efficiency result in minimal material waste, further lowering production costs.

Future Prospects of Industrial Robotics:

The future of industrial robotics holds immense potential. With advancements in artificial intelligence (AI) and machine learning, robots are becoming smarter and more adaptable. They can now learn from their surroundings, make autonomous decisions, and collaborate with human workers seamlessly. This integration of human and robotic workforce is expected to revolutionize the manufacturing industry, creating a more efficient and flexible production environment.

Conclusion:

Industrial robots have undoubtedly transformed the manufacturing industry, offering increased efficiency, enhanced precision, improved safety, and cost savings. As technology continues to evolve, the capabilities of industrial robots will only expand, further revolutionizing manufacturing processes. Embracing this innovative technology is crucial for companies looking to stay competitive in today's fast-paced manufacturing landscape.

Check out the latest advancements in industrial robot technology and discover how they can revolutionize your manufacturing processes. Contact us today to explore the possibilities and find the perfect solution for your business needs. Industrial Robot

"Enhancing Manufacturing Efficiency with Cutting-Edge Industrial Robotics: Unveiling the Power of Robotic Arms & CPUs in the World of Industrial Automation"