Check out the leading manufacturer for a professional coil packing solution here:

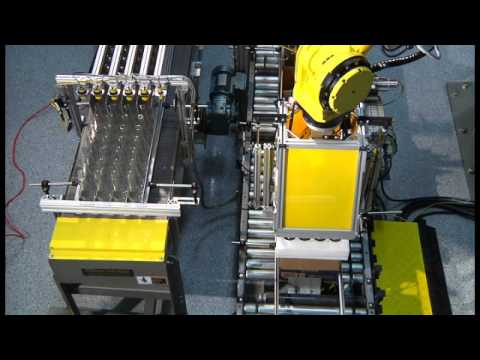

Title: Enhancing Efficiency in Glass Container Packaging with FANUC Robotic Soft-Packer

Introduction:

In today's fast-paced manufacturing industry, efficiency and precision are key factors in ensuring successful production processes. This rings especially true for the packaging of delicate glass containers, where any mis-pack or damage can result in significant losses. To address these challenges, FANUC, a renowned leader in industrial automation, has developed the Robotic Soft-Packer for Glass Containers with Integrated Carrier/Divider Inspector and Mis-Pack Detector for Go/No-Go. This innovative solution combines advanced robotics with cutting-edge inspection technology to optimize the packaging process and minimize errors. In this article, we will explore the features and advantages of this system, as well as its integration with a used packing system.

Explanatory Style:

The FANUC Robotic Soft-Packer is equipped with state-of-the-art technology that revolutionizes the packaging of glass containers. By integrating a carrier/divider inspector and mis-pack detector, this system ensures that each container is accurately placed within the packaging, eliminating the risk of mis-packs. This not only guarantees the integrity of the products but also reduces the potential for damages during transportation.

One of the key advantages of this solution is its ability to integrate seamlessly with a used packing system. By harnessing the power of robotics, FANUC enables manufacturers to upgrade their existing packing systems without the need for a complete overhaul. This cost-effective approach allows businesses to enhance their packaging operations without significant investments.

In addition to its compatibility with used packing systems, the FANUC Robotic Soft-Packer offers a range of features that optimize efficiency. Its intelligent robotic arm ensures precise and gentle handling of glass containers, minimizing the risk of breakage. The integrated carrier/divider inspector identifies any defects or abnormalities in the packaging materials, guaranteeing that only quality containers are used. Furthermore, the mis-pack detector performs a Go/No-Go analysis, ensuring that each product is correctly positioned within the packaging.

Case Study Style:

To illustrate the real-world impact of the FANUC Robotic Soft-Packer, let's consider a glass container manufacturer that recently implemented this system. Prior to the integration, the company faced significant challenges in maintaining product quality and reducing packaging errors. With the FANUC solution, they were able to streamline their packaging process and eliminate mis-packs entirely. This led to a notable decrease in customer complaints and returns, ultimately enhancing their brand reputation.

Predictive/Foresight Style:

Looking ahead, the FANUC Robotic Soft-Packer is set to revolutionize the glass container packaging industry. With its advanced technology and seamless integration capabilities, it offers a cost-effective solution for manufacturers to optimize their packaging operations. As automation continues to evolve, we can expect further advancements in robotics and inspection technology, ultimately leading to even greater efficiency and precision in the future.

Conclusion:

In conclusion, the FANUC Robotic Soft-Packer for Glass Containers with Integrated Carrier/Divider Inspector and Mis-Pack Detector for Go/No-Go represents a significant advancement in glass container packaging. By combining cutting-edge robotics with advanced inspection technology, this solution ensures accuracy, efficiency, and product integrity. Its compatibility with used packing systems makes it an attractive option for manufacturers looking to upgrade their packaging processes without major investments. With FANUC's commitment to innovation, the future of glass container packaging looks brighter than ever.

Check out the leading manufacturer for a professional coil packing solution here: [Insert link to manufacturer's website] Packing System

"Revolutionizing Glass Case Packaging: Discover the Ultimate Robotic System for Optimal Efficiency and Sustainability"