Title: Fully Automated Packing and Palletising with OCTOPUS | Automated Packing Systems

Description:

Introduction:

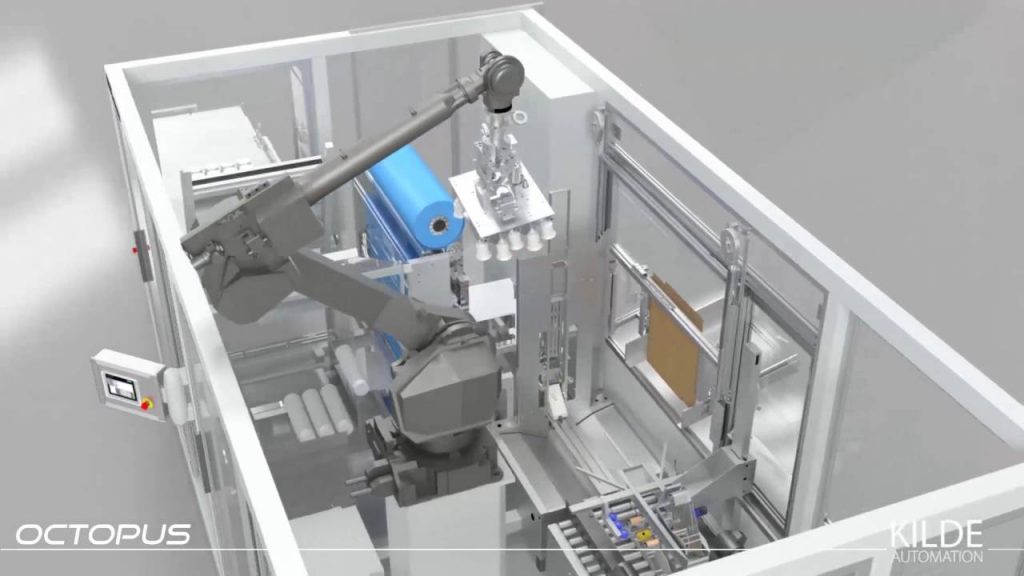

Welcome to our video showcasing the OCTOPUS - a cutting-edge, fully automated packing and palletising machine offered by Automated Packing Systems. In this video, we will explore the capabilities and features of this remarkable technology, which efficiently stacks thermoformed parts into stacks of a predefined length and seals them securely.

Video Content:

The OCTOPUS is revolutionizing the packing and palletising process with its advanced automation capabilities. With precision and speed, this machine seamlessly organizes and stacks thermoformed parts, ensuring optimal efficiency in your packaging operations. Say goodbye to manual labor and hello to increased productivity!

Key Highlights and Operation Steps:

1. High-speed Stacking: The OCTOPUS excels at stacking thermoformed parts quickly and accurately, thanks to its intelligent design and advanced algorithms. It can handle a wide range of part sizes and shapes with ease.

2. Predefined Stack Length: This packing system allows you to set a predefined stack length, ensuring consistency and uniformity in your packaging. This feature contributes to enhanced load stability and ease of transportation.

3. Secure Sealing: The OCTOPUS ensures that each stack is securely sealed, providing protection against damage during handling and transit. This feature is crucial for maintaining the quality and integrity of your products.

4. Customizable Options: Tailor the OCTOPUS to your specific packaging needs. This machine offers various customization options, including adjustable stack heights, sealing methods, and stacking patterns.

Call to Action:

If you are looking to optimize your packing and palletising processes, the OCTOPUS is the perfect solution for your business. Like, subscribe, and share this video to stay updated with the latest advancements in automated packing systems. For more information and to explore how the OCTOPUS can benefit your operations, contact our team at [Insert Contact Information].

Additional Tags and Keywords:

automated packing systems, OCTOPUS packing machine, palletising technology, stack length control, sealing efficiency, precision stacking, advanced packaging technology, productivity enhancement, customizable packing solutions.

Hashtags:

#AutomatedPackingSystems #OCTOPUSPackingMachine #PalletisingTechnology #AdvancedPackagingSolutions #EfficientStacking #ProductivityEnhancement

Title: OCTOPUS: Revolutionizing Packaging and Palletizing with Automation

Introduction:

In today's fast-paced world, industries are constantly seeking innovative solutions to increase efficiency and productivity. OCTOPUS, a cutting-edge automated system, is transforming the packaging and palletizing process completely. This article explores the features and benefits of OCTOPUS, highlighting its potential to revolutionize the industry.

1. Increased Efficiency:

OCTOPUS eliminates the need for manual labor in the packaging and palletizing process. With its advanced robotic arms and intelligent algorithms, it can seamlessly handle various packaging materials, sizes, and shapes. This automation significantly reduces the time required for packing and palletizing, leading to substantial improvements in overall efficiency.

2. Enhanced Precision:

The intelligent algorithms of OCTOPUS ensure accurate placement of the products on pallets. This eliminates the risk of errors that are common in manual operations. With precise positioning, OCTOPUS minimizes product damage and optimizes space utilization, leading to cost savings and customer satisfaction.

3. Versatile Packaging Capabilities:

OCTOPUS is designed to handle a wide range of products, from boxes and cartons to bags, containers, and more. It can adapt to different packaging requirements effortlessly, making it ideal for industries with diverse product portfolios. Its versatility enhances operational flexibility and eliminates the need for multiple packaging systems.

4. Intelligent Software Integration:

The OCTOPUS system is equipped with intelligent software that integrates seamlessly with existing warehouse management systems. This integration enables real-time data exchange, allowing for efficient inventory management, order tracking, and production planning. The software also provides detailed reports and analytics, empowering businesses to make data-driven decisions.

5. Safety and Reliability:

OCTOPUS prioritizes safety with its advanced sensors and safety mechanisms. The robotic arms are programmed to detect obstacles and adjust their movements accordingly, reducing the risk of accidents. Moreover, the system undergoes rigorous testing and quality control measures to ensure reliability and durability, minimizing downtime and maintenance costs.

6. Cost Savings:

By automating the packaging and palletizing process, OCTOPUS reduces labor costs significantly. The system operates continuously with minimal supervision, eliminating the need for additional hires. Additionally, its optimized space utilization and reduced product damage lead to substantial savings in storage and transportation expenses.

Conclusion:

OCTOPUS represents a leap forward in packaging and palletizing automation, offering a myriad of benefits for industries seeking increased efficiency, precision, and cost savings. With its versatility, intelligent software integration, and emphasis on safety, OCTOPUS is poised to revolutionize the way products are packed and palletized. Embracing this fully automated system can enable businesses to stay ahead of the competition and adapt to the demands of modern manufacturing. Automatic Packing Line

#OCTOPUS #Fully #automated #packing #palletising