Ever more emphasis is being placed on ecological factors, especially in the field of packaging technology. As our energy resources are depleting and environmental concerns are growing, businesses are realizing the importance of adopting eco-friendly practices. One area where sustainability is gaining traction is in shrink tunnel machines, which play a crucial role in packaging operations.

Shrink tunnel machines are widely used in the packaging industry to provide a tight and secure wrap around products. They use heat to shrink plastic film, creating a protective layer around the item being packaged. This not only ensures product integrity during transportation and storage but also enhances the overall presentation of the packaged goods.

In recent years, the demand for shrink tunnel machines that are environmentally friendly has been on the rise. Businesses are actively seeking solutions that minimize their carbon footprint and reduce waste. This shift in mindset is driven by a growing awareness of the impact of packaging materials on the environment.

One of the leading manufacturers in the market, KHS Innopack, has recognized this trend and developed the Kisters ST shrink tunnel. This innovative machine combines cutting-edge technology with eco-friendly features, making it a top choice for businesses looking to enhance their sustainability efforts.

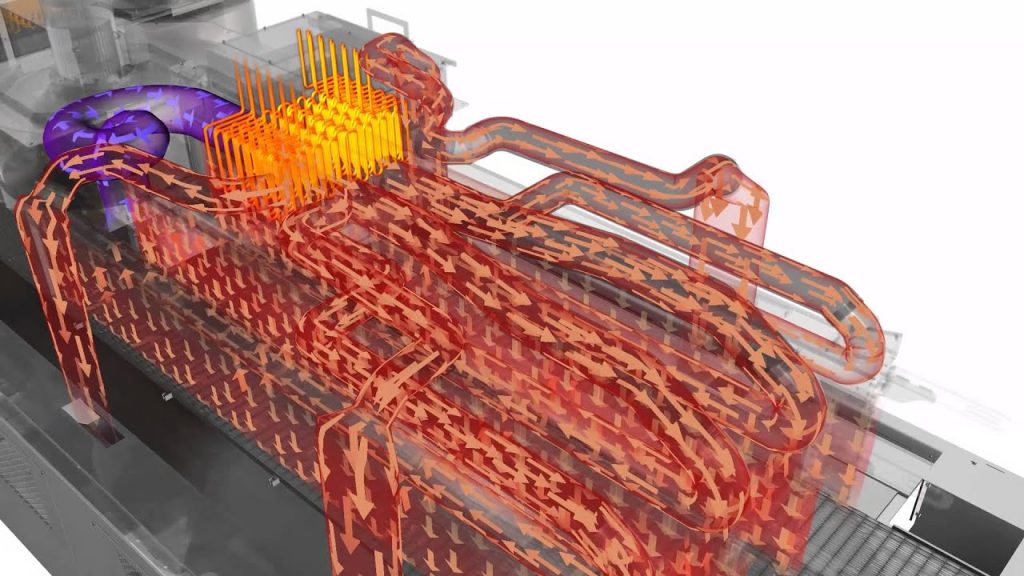

The Kisters ST shrink tunnel is designed to optimize energy consumption while maintaining high-performance standards. It incorporates advanced insulation materials and energy-efficient components, resulting in significant energy savings. By reducing energy consumption, businesses not only contribute to environmental preservation but also enjoy cost savings in the long run.

Furthermore, the Kisters ST shrink tunnel is equipped with intelligent controls that ensure precise temperature regulation. This feature eliminates the risk of overheating and prevents unnecessary energy wastage. The machine also offers adjustable conveyor speeds, allowing businesses to customize the packaging process according to their specific requirements. This flexibility leads to further energy savings and improved operational efficiency.

In addition to its eco-friendly attributes, the Kisters ST shrink tunnel delivers exceptional performance and reliability. Its robust construction and high-quality materials guarantee longevity and durability. This reduces the need for frequent repairs and replacements, resulting in reduced waste generation.

The Kisters ST shrink tunnel is also designed with user convenience in mind. Its user-friendly interface and intuitive controls make it easy to operate and maintain. This not only saves time but also enhances productivity.

In conclusion, the increasing focus on ecological factors in the packaging industry has led to the development of eco-friendly shrink tunnel machines. The Kisters ST shrink tunnel from KHS Innopack is a prime example of a sustainable solution that combines energy efficiency, performance, and reliability. By investing in such eco-friendly technologies, businesses can align their packaging operations with their sustainability goals and contribute to a greener future.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Shrinking Machine

"Efficient Shrink Tunnel Machines for Packaging: Boost Productivity with KHS Innopack Kisters ST"