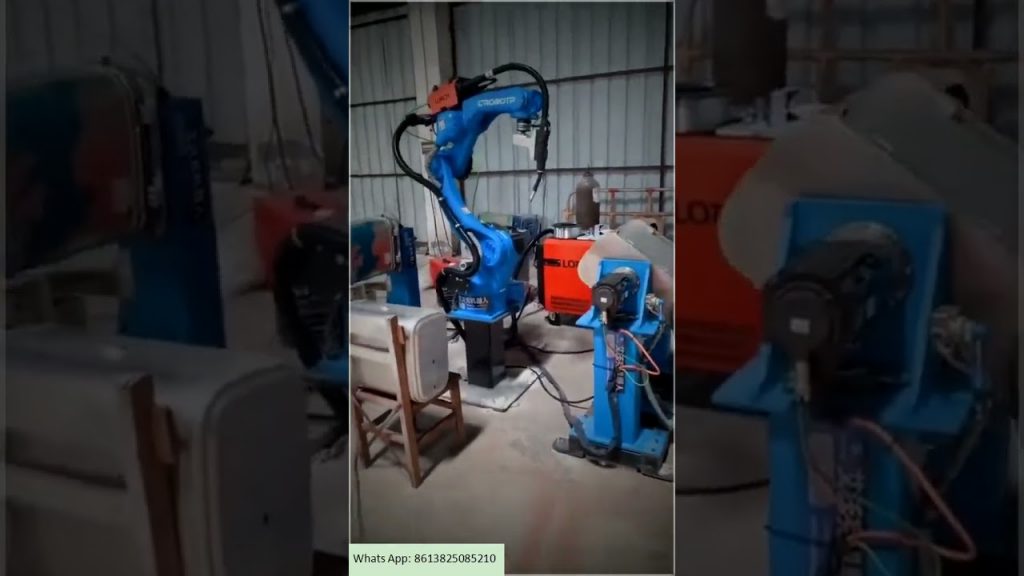

Check out our video on YouTube to learn more about our factory that specializes in manufacturing industrial robotic arms for various applications such as arc welding, loading and unloading, stamping, palletizing, and more. With our expertise in robotic arm technology, we can provide you with high-quality solutions for your automation needs.

Industrial Robotic Arm: Enhancing Efficiency and Productivity

In today's fast-paced manufacturing industry, the demand for automation has never been higher. Industrial robotic arms have become an indispensable tool for businesses looking to increase their efficiency and productivity. These versatile machines are capable of performing a wide range of tasks with precision and accuracy, making them an ideal choice for various industries.

One of the key advantages of industrial robotic arms is their ability to perform arc welding. With their six-axis movement capabilities, these robots can easily maneuver around complex shapes and weld with great precision. Whether it's joining two pieces of metal or creating intricate weld patterns, our robotic arms can handle it all. By automating the welding process, businesses can significantly improve the quality and consistency of their welds while reducing costs associated with manual labor.

Loading and unloading tasks can also be efficiently handled by our industrial robotic arms. Whether it's loading and unloading heavy parts onto a production line or transferring finished products to a packaging area, our robots can handle the job with ease. With their soft grippers, these robots can securely hold and manipulate objects of various shapes and sizes, ensuring a smooth and efficient workflow.

Stamping is another application where our industrial robotic arms excel. These machines can be programmed to precisely position and press down on metal sheets to create intricate designs or shapes. By automating the stamping process, businesses can achieve consistent results, reduce errors, and increase production output.

Palletizing, the process of arranging products or materials onto pallets, is yet another task that our industrial robotic arms can handle efficiently. These robots can quickly and accurately stack boxes, bags, or other items onto pallets, ensuring a neat and organized arrangement. By automating the palletizing process, businesses can save time and labor costs while increasing overall productivity.

At our factory, we specialize in designing and manufacturing industrial robotic arms that meet the specific needs of our customers. Our team of experienced engineers works closely with clients to understand their requirements and provide tailored solutions. Whether you need a robotic arm for arc welding, loading and unloading, stamping, palletizing, or any other application, we have the expertise to deliver top-notch solutions.

In conclusion, industrial robotic arms are revolutionizing the manufacturing industry by enhancing efficiency and productivity. With their capabilities in arc welding, loading and unloading, stamping, palletizing, and more, these robots are proving to be invaluable assets for businesses worldwide. If you're looking for a reliable and experienced manufacturer of industrial robotic arms, look no further. Contact us today to discuss your automation needs and let us provide you with the perfect solution.

Check out our YouTube video to see our industrial robotic arms in action and learn more about how they can benefit your business. Industrial Robotic Arm - Revolutionizing Automation. Industrial Robot

"Efficient Welding Solutions: Unveiling the Versatile Soft Gripper and Six Axis Robot Arm for Industrial Tooling and Fixtures"