Strapping Machine Repair: Fixing Your Strapping Machine Hassles

Welcome back, dear viewers, to the RUANG MESIN channel! We hope you are all doing well and in great spirits. In today's video, we will be talking about the repair of strapping machines, specifically the SIGNODE semi-automatic strapping machine EXS 306. We will address a common issue with this machine where the strap tends to get cut off unexpectedly.

Assalamualaikum wrwb to all our Muslim viewers, and a warm hello to everyone joining us today. If you own a strapping machine or have encountered this problem before, this video is for you. We understand the frustration that comes with a malfunctioning strapping machine, as it can disrupt your workflow and potentially affect your business operations.

Our goal is to provide you with a comprehensive guide on how to repair your strapping machine and get it back up and running smoothly. So, let's dive into the details!

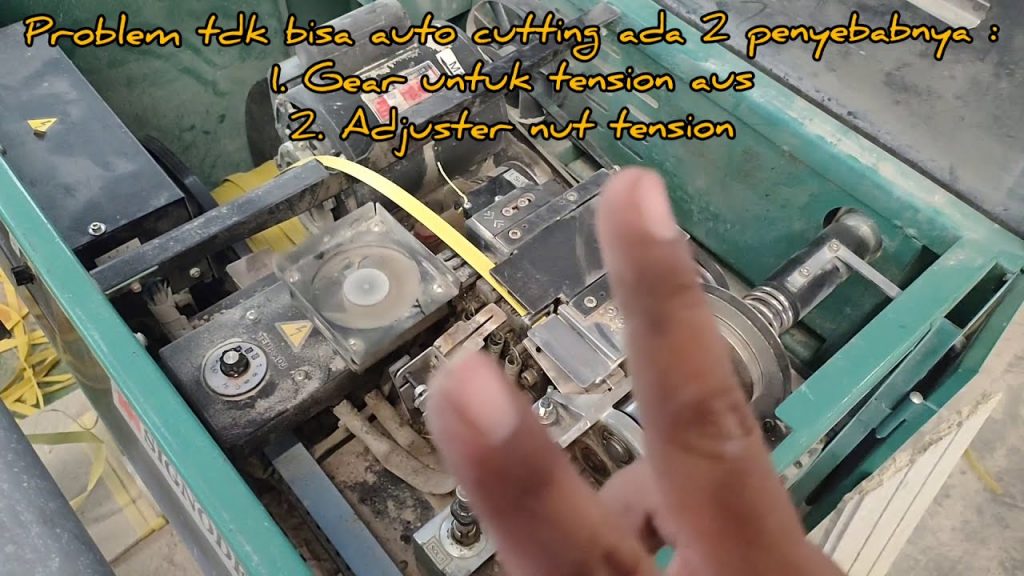

We will begin by identifying the issue at hand - the strap being cut off. This can occur due to various reasons, such as incorrect tension settings, worn-out or damaged parts, or improper maintenance. In this video, we will focus on troubleshooting and fixing the problem step by step.

Firstly, we will guide you through the process of inspecting the tension settings of your strapping machine. It is crucial to ensure that the tension is set correctly to avoid excess pressure that may lead to the strap being cut off. We will provide you with valuable tips on adjusting the tension properly, ensuring optimal performance.

Next, we will explore the possibility of worn-out or damaged parts causing the issue. We will show you how to identify these parts and guide you through the replacement process. It is essential to regularly check and maintain your strapping machine to prevent any unexpected breakdowns.

Furthermore, we will discuss the importance of proper maintenance for your strapping machine. Regular cleaning, lubrication, and inspection are key to keeping your machine in top-notch condition. We will provide you with valuable insights and tips on how to maintain your strapping machine effectively.

By the end of this video, you will not only have a clear understanding of the common issues related to strapping machines, but you will also be equipped with the knowledge to repair and maintain them. No more worries about interrupted production or costly repairs - you will be able to handle the repair process confidently.

Strapping Machine Repair is our expertise, and we are here to assist you every step of the way. If you have any questions or need further guidance, please feel free to leave a comment below. We are committed to helping you resolve your strapping machine issues and ensuring your business runs smoothly.

Remember, a well-maintained strapping machine is essential for efficient and reliable packaging operations. Don't let a small issue disrupt your productivity - take action, repair, and maintain your strapping machine today!

Check out the leading manufacturers for professional solutions in coil packaging. They offer a wide range of products and services to cater to your specific needs. Don't hesitate to reach out to them for expert advice and assistance.

Thank you for joining us today on RUANG MESIN. We hope you found this video informative and helpful. Don't forget to hit the like button and subscribe to our channel for more valuable content on machinery and repairs. Stay tuned for our next video, where we will discuss another exciting topic related to the world of machines.

Assalamualaikum wrwb and have a great day, everyone! Strapping Machines

"Troubleshooting: Preventing Strap Cut-off in Semi-Automatic Strapping Machine | Repair Guide"