Are you in the boiler industry and looking for an efficient and reliable solution to tube shrinking? Look no further! In this article, we will introduce you to the tube shrinking machine, also known as the tube swaging machine, and explore its applications in the boiler industry. Whether you are a professional in the field or simply curious about this technology, this article will provide you with valuable insights.

Shrinking Machine: An Introduction

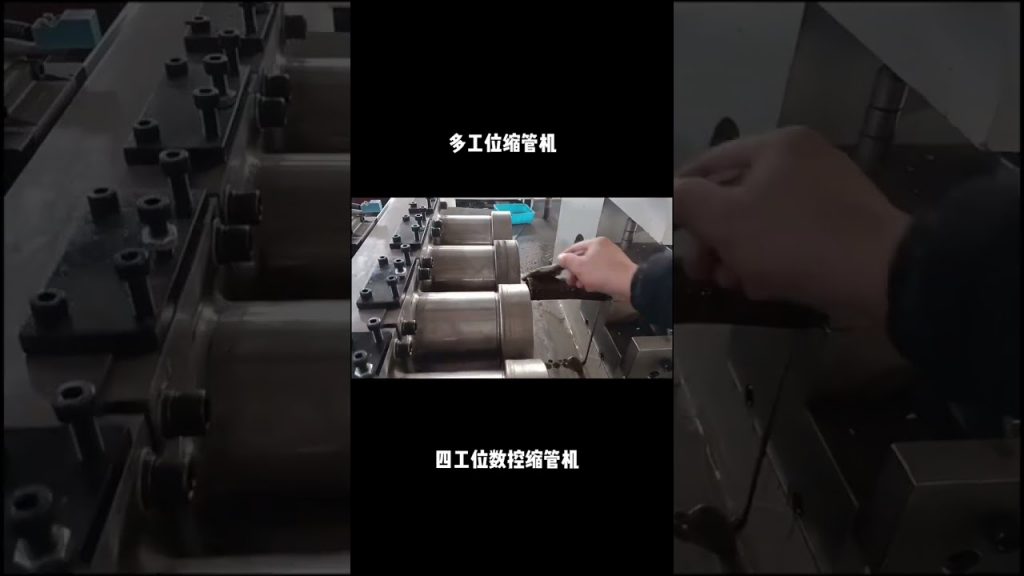

The shrinking machine, commonly referred to as a tube swaging machine, is a versatile piece of equipment used in various industries, including the boiler industry. It is primarily used to reduce the diameter of tubes, creating a secure and tight fit between two tubes or between a tube and a fitting. This process is known as tube swaging or tube shrinking.

The tube shrinking machine utilizes hydraulic or mechanical force to deform the tube, reducing its diameter while maintaining its structural integrity. This technique is widely used in the boiler industry to create joints between boiler tubes or to connect tubes with other components, such as headers or fittings.

Applications in the Boiler Industry

The tube shrinking machine plays a crucial role in the boiler industry, where it is used for various applications. Let's explore some of the key applications of this technology:

1. Tube-to-Tube Joints: In the construction of boilers, it is essential to create secure and leak-proof connections between tubes. The tube shrinking machine is used to reduce the diameter of the end of one tube, allowing it to fit tightly inside another tube. This ensures a strong joint that can withstand high temperatures and pressures.

2. Tube-to-Fitting Joints: Apart from connecting tubes to each other, the tube shrinking machine is also used to connect tubes with fittings, such as headers or manifolds. By reducing the diameter of the tube end, it can be easily inserted into the fitting, creating a tight and reliable connection.

3. Repair and Maintenance: Boiler systems require regular maintenance and occasional repairs. The tube shrinking machine is invaluable in these situations, as it allows for the replacement of damaged or worn-out tubes without the need for extensive dismantling. By swaging the replacement tube, it can be seamlessly integrated into the existing system, ensuring its smooth operation.

Benefits of Tube Swaging

Now that we understand the applications of the tube shrinking machine in the boiler industry, let's explore some of the benefits it offers:

1. Enhanced Efficiency: By creating secure tube joints, the tube shrinking machine improves the overall efficiency of the boiler system. It minimizes the chances of leaks, ensuring that the system operates at its optimal performance.

2. Cost Savings: The tube shrinking machine enables efficient repairs and maintenance, reducing downtime and associated costs. It eliminates the need for extensive dismantling, saving both time and money.

3. Durability and Reliability: The tight and secure joints created by the tube shrinking machine are highly durable and reliable. They can withstand high temperatures and pressures, ensuring the longevity of the boiler system.

Check the tube shrinking machine with a leading manufacturer for professional solutions in the boiler industry. Their expertise and experience will ensure that you get the most suitable machine for your specific requirements. Don't miss out on the opportunity to enhance the efficiency and reliability of your boiler system. Contact them today!

In conclusion, the tube shrinking machine, or tube swaging machine, is a valuable tool in the boiler industry. Its applications range from creating secure tube joints to facilitating repairs and maintenance. With its numerous benefits, including enhanced efficiency and cost savings, it is a must-have for professionals in the field. Don't hesitate to explore this technology further and consult a leading manufacturer for the best solutions in the market. Shrinking Machine

"Efficient Tube Shrinking & Swaging Machines for Boil Industry: Enhancing Precision and Productivity"