Title: PH Cell 2000 - Modular Pallet Handling Machine with Twin Fork Technology

Description:

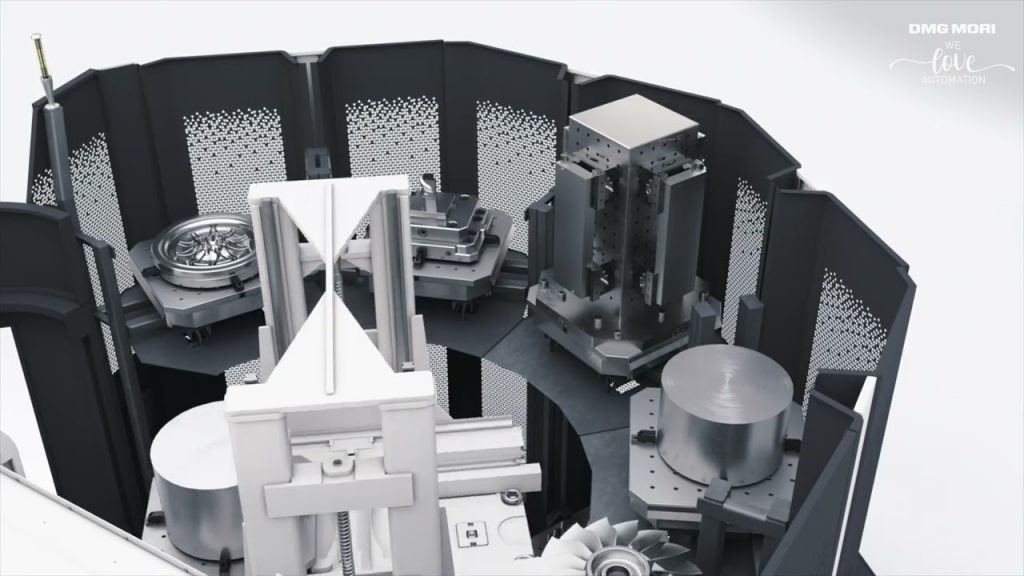

Welcome to our video showcasing the PH Cell 2000, a state-of-the-art pallet handling machine designed to streamline your warehouse operations. With its innovative Twin Fork Technology and modular design, this system offers unrivaled efficiency and flexibility.

Overview:

In this video, we will delve into the features and capabilities of the PH Cell 2000, highlighting its key advantages and specifications. From its compact footprint of just 16.5 m2, this machine boasts a modular rotary pallet storage system capable of accommodating up to 21 pallets. With a maximum transfer weight of 2000 kg, you can easily handle heavy loads with ease.

Key Highlights:

- Modular Rotary Pallet Storage: The PH Cell 2000 optimizes space utilization by incorporating a modular rotary pallet storage system. This design allows for efficient storage and retrieval of up to 21 pallets, minimizing the need for extra floor space.

- Twin Fork Technology: Equipped with Twin Fork Technology, this pallet handling machine ensures secure and stable pallet handling, reducing the risk of accidents and improving overall operational safety.

- Versatile Pallet Size Compatibility: The PH Cell 2000 accommodates various pallet sizes, making it suitable for a wide range of industries and applications.

Video Content:

In this video, we will guide you through the operation steps of the PH Cell 2000, showcasing its seamless pallet handling capabilities. From loading and unloading pallets to its advanced control system, you will gain a comprehensive understanding of how this machine can revolutionize your warehouse processes.

Call to Action:

If you found this video informative and useful, we encourage you to give it a thumbs up, subscribe to our channel for more insightful content, and share it with your colleagues. Stay updated with the latest advancements in pallet handling technology by joining our community.

Additional Tags and Keywords:

Pallet Handling Machine, PH Cell 2000, Twin Fork Technology, Modular Pallet Storage, Warehouse Automation, Efficient Pallet Handling, Heavy Load Handling, Warehouse Operations, Warehouse Efficiency

Hashtags:

#PalletHandlingMachine #PHCell2000 #TwinForkTechnology #ModularPalletStorage #WarehouseAutomation #WarehouseEfficiency

Title: PH Cell 2000 - Revolutionizing Pallet Handling with Twin Fork Technology

Introduction:

The PH Cell 2000 is an innovative modular pallet handling system that incorporates Twin Fork Technology, aiming to optimize efficiency and productivity in pallet handling operations. This cutting-edge solution offers a versatile and automated approach to streamline the movement and manipulation of pallets, ensuring seamless integration into various industries. In this article, we will explore the remarkable features and benefits of the PH Cell 2000, highlighting its ability to revolutionize pallet handling processes.

1. Twin Fork Technology:

The PH Cell 2000 introduces the revolutionary Twin Fork Technology, enabling simultaneous handling of two pallets. This advanced system provides increased throughput and reduced cycle times, enhancing operational efficiency. By eliminating the need for multiple handling devices, the Twin Fork Technology significantly minimizes downtime and maximizes productivity, making it an ideal choice for high-volume pallet handling applications.

2. Modular Design:

Designed with flexibility in mind, the PH Cell 2000 offers a modular design that can be easily customized to meet specific requirements. This adaptability allows businesses to optimize their pallet handling operations by tailoring the system to their unique workflow and space constraints. The modular nature of the PH Cell 2000 ensures future scalability, enabling seamless expansion as business needs evolve.

3. Automated Handling:

With its state-of-the-art automation capabilities, the PH Cell 2000 reduces reliance on manual labor, thereby minimizing the risk of human error and increasing overall safety. Equipped with advanced sensors and intelligent controls, this system ensures precise and accurate pallet handling, eliminating potential damages to goods and enhancing product integrity. By automating repetitive and labor-intensive tasks, businesses can allocate their workforce to more value-added activities, boosting overall productivity.

4. Seamless Integration:

The PH Cell 2000 seamlessly integrates into existing production lines and warehouse management systems, facilitating a smooth transition without disrupting ongoing operations. Its compatibility with various pallet types and sizes allows businesses to handle diverse products efficiently. The system's user-friendly interface and intuitive controls further enhance its integration capabilities, enabling easy operation and maintenance.

5. Enhanced Efficiency and Cost Savings:

The PH Cell 2000's ability to handle multiple pallets simultaneously, combined with its automation capabilities, significantly increases operational efficiency. By reducing cycle times and minimizing handling errors, businesses can achieve higher throughput and greater productivity. The system's efficient use of space, coupled with its modular design, leads to optimal resource utilization and cost savings in terms of both time and labor.

Conclusion:

The PH Cell 2000 with Twin Fork Technology represents a groundbreaking solution for pallet handling operations. Its innovative features, including simultaneous handling of two pallets, modular design, automated capabilities, seamless integration, and enhanced efficiency, make it an ideal choice for businesses looking to optimize their pallet handling processes. By investing in this advanced system, companies can revolutionize their operations, increase productivity, and gain a competitive edge in the market.Handling Machine

#Cell #Modular #pallet #handling #system #Twin #Fork #Technology