Check out the leading manufacturer for a professional coil packing solution here:

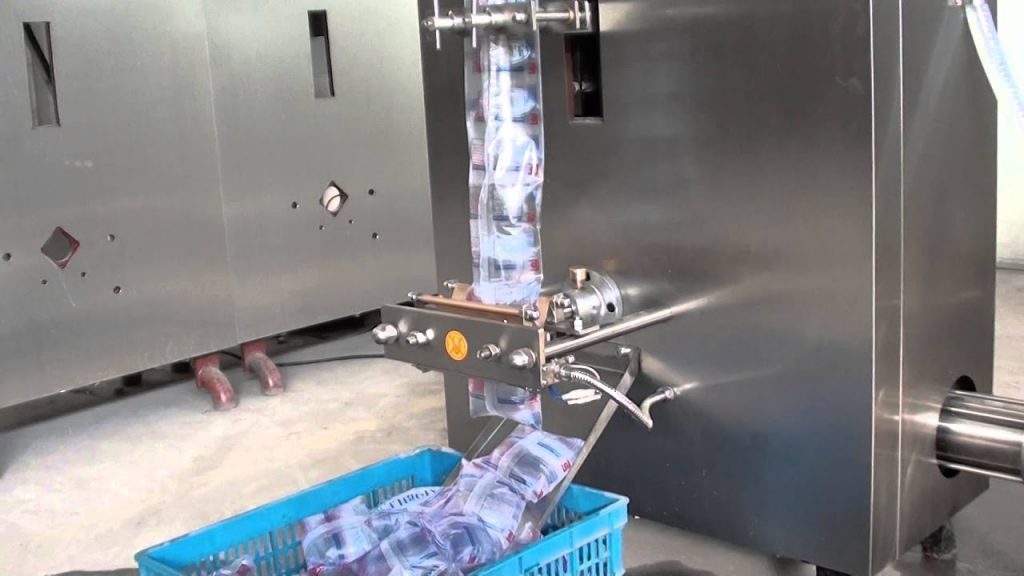

Introducing the KOYO Water Sachet Filling and Sealing Machine: A Breakthrough in Automatic Filling Packing Technology

In today's fast-paced world, convenience is key. This is especially true when it comes to packaging and sealing machines. With the increasing demand for efficient and reliable packaging solutions, the KOYO Water Sachet Filling and Sealing Machine emerges as a game-changer in the industry. Let's dive into the details of this revolutionary Automatic Filling Packing Machine.

Narrative Structure:

Imagine a world where every drop of water is perfectly packaged and sealed, ready to be consumed. The KOYO Water Sachet Filling and Sealing Machine brings this vision to life. This advanced machine is designed to fill and seal water sachets with precision and efficiency. Its cutting-edge technology ensures that every sachet is sealed securely, keeping the water fresh and uncontaminated.

The KOYO Water Sachet Filling and Sealing Machine is equipped with automatic filling and packing features, making it incredibly user-friendly. Its intuitive interface allows operators to easily control the machine and adjust settings according to their specific requirements. With just a few simple steps, the machine can be set up and ready to go.

This state-of-the-art machine boasts a high production capacity, capable of filling and sealing hundreds of sachets per minute. This makes it an ideal choice for industries that require large-scale packaging, such as beverage companies, hospitality services, and more. With the KOYO Water Sachet Filling and Sealing Machine, businesses can streamline their packaging process and meet the growing demands of their customers.

But what sets the KOYO Water Sachet Filling and Sealing Machine apart from its competitors? One of its key features is its versatility. This machine is not limited to water sachets alone. It can also be used to fill and seal other liquid products such as juices, oils, and even sauces. This flexibility makes it a valuable asset for businesses operating in various industries.

Furthermore, the KOYO Water Sachet Filling and Sealing Machine is built with durability in mind. Its robust construction ensures longevity, reducing maintenance costs and downtime. This reliability is crucial for businesses that rely on continuous production and cannot afford any disruptions.

Argumentative Structure:

The KOYO Water Sachet Filling and Sealing Machine is a game-changer in the industry of packaging and sealing machines. Its automatic filling and packing features, high production capacity, and versatility make it a top choice for businesses looking to optimize their packaging process.

With this machine, businesses can increase their productivity and efficiency. The high-speed filling and sealing capabilities of the KOYO Water Sachet Filling and Sealing Machine allow for faster packaging, reducing bottlenecks in the production line. This ultimately leads to higher output and improved customer satisfaction.

Moreover, the machine's versatility opens up opportunities for businesses to diversify their product offerings. By utilizing the KOYO Water Sachet Filling and Sealing Machine for different liquid products, businesses can tap into new markets and cater to a wider range of customers.

In addition, the durability of the KOYO Water Sachet Filling and Sealing Machine ensures a long lifespan, minimizing downtime and maintenance costs. Investing in a reliable machine like this can save businesses money in the long run and contribute to their overall profitability.

Whether you are a beverage company, a hospitality service, or any other industry that requires efficient packaging solutions, the KOYO Water Sachet Filling and Sealing Machine is your answer. Embrace the future of automatic filling packing technology and experience the benefits firsthand.

Check out the leading manufacturer for a professional coil packing solution here: Filling Packing Machine

"Efficient Water Sachet Filling and Sealing Machine: Simplify Packaging Process with Automatic Technology!"