Check out the leading manufacturer for a professional solution here: [URL]

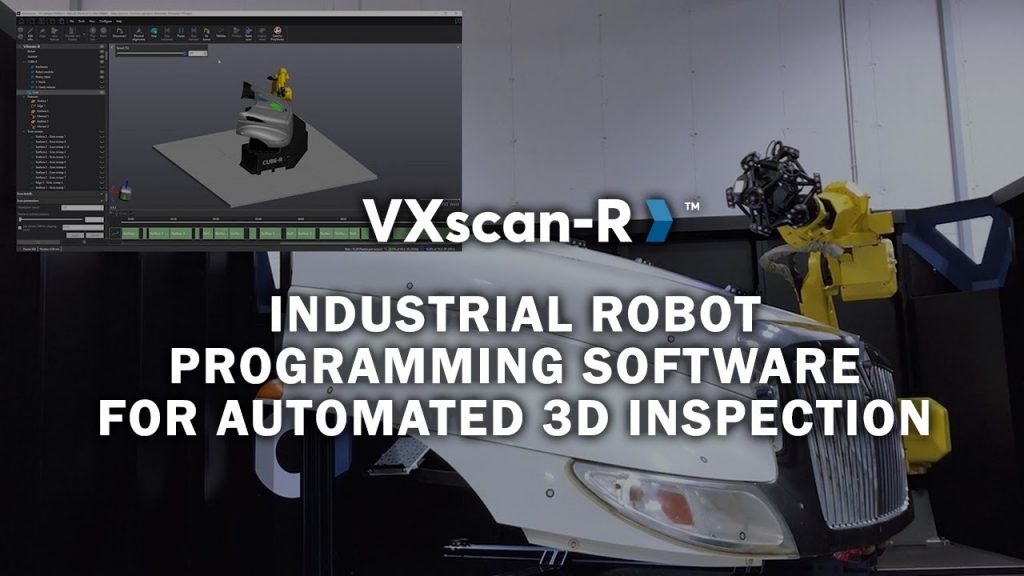

Title: Industrial Robot Programming for Automated 3D Inspection Made Easy with VXscan-R

Introduction:

In today's fast-paced industrial landscape, efficiency and accuracy are key factors that determine success. Industrial robot programming plays a crucial role in automating various processes, including 3D inspection. With the advent of advanced software solutions like Creaform VXscan-R, industrial robot programming has become simpler and more efficient than ever before. In this article, we will dive into the world of industrial robot programming and explore how the VXscan-R software revolutionizes automated 3D inspection.

Overview of Industrial Robot Programming:

Industrial robot programming involves the creation and implementation of instructions for industrial robots to perform specific tasks. These instructions are typically written using specialized programming languages and are designed to optimize the robot's movements, accuracy, and efficiency. By automating tasks that would otherwise require human intervention, industrial robot programming helps businesses streamline their operations and achieve higher productivity levels.

Introducing VXscan-R: Industrial Robot Programming Software for Automated 3D Inspection:

VXscan-R, developed by Creaform, is a cutting-edge software solution designed to simplify industrial robot programming for automated 3D inspection. With its user-friendly interface and powerful features, VXscan-R empowers businesses to perform accurate and efficient inspections with ease. Let's take a closer look at some of its key features and benefits:

1. Intuitive Interface: VXscan-R boasts an intuitive interface that allows users to effortlessly program industrial robots for automated 3D inspection. Even individuals with limited programming experience can quickly adapt to the software and start programming robots within a short span of time.

2. Precise Path Planning: The software leverages advanced algorithms to calculate precise robot paths, ensuring optimal coverage during the 3D inspection process. This results in improved accuracy and efficiency, reducing the likelihood of errors and rework.

3. Real-time Monitoring and Analysis: VXscan-R provides real-time monitoring and analysis capabilities, allowing operators to track the progress of the inspection and make necessary adjustments on the fly. This feature enables quick decision-making and enhances overall process control.

4. Seamless Integration: The software seamlessly integrates with a wide range of industrial robot models, making it versatile and adaptable to various automation setups. This flexibility ensures compatibility with existing systems, eliminating the need for costly hardware upgrades.

Case Study: Enhancing Quality Assurance with VXscan-R:

To further illustrate the capabilities of VXscan-R, let's explore a real-world case study where the software was used to enhance quality assurance in a manufacturing facility. [Describe the case study scenario, highlighting the challenges faced, how VXscan-R was implemented, and the positive outcomes achieved.]

Conclusion:

Industrial robot programming plays a critical role in automating 3D inspection processes, leading to increased efficiency and accuracy in industrial operations. With software solutions like VXscan-R, businesses can streamline their workflows, enhance quality assurance, and achieve greater productivity. Embracing the advancements in industrial robot programming is key to staying competitive in today's rapidly evolving industry.

Check out the leading manufacturer for a professional solution here: [URL] Industrial Robot

"Streamline 3D Inspection with VXscan-R: Advanced Industrial Robot Programming Software for Efficient Automation"