Plastic Injection Molding Machine: Your Best ROI with PowerJet KPET3105L E6

Are you looking to enhance your PET preform injection molding process? Look no further than the PowerJet KPET3105L E6 with 72 cavities. With its advanced technology and high efficiency, this machine offers the best return on investment for your plastic injection molding needs.

In this article, we will explore the features and benefits of the PowerJet KPET3105L E6, and how it can significantly improve your manufacturing process. Whether you are new to the industry or an experienced professional, this machine is designed to meet your specific requirements and deliver outstanding results.

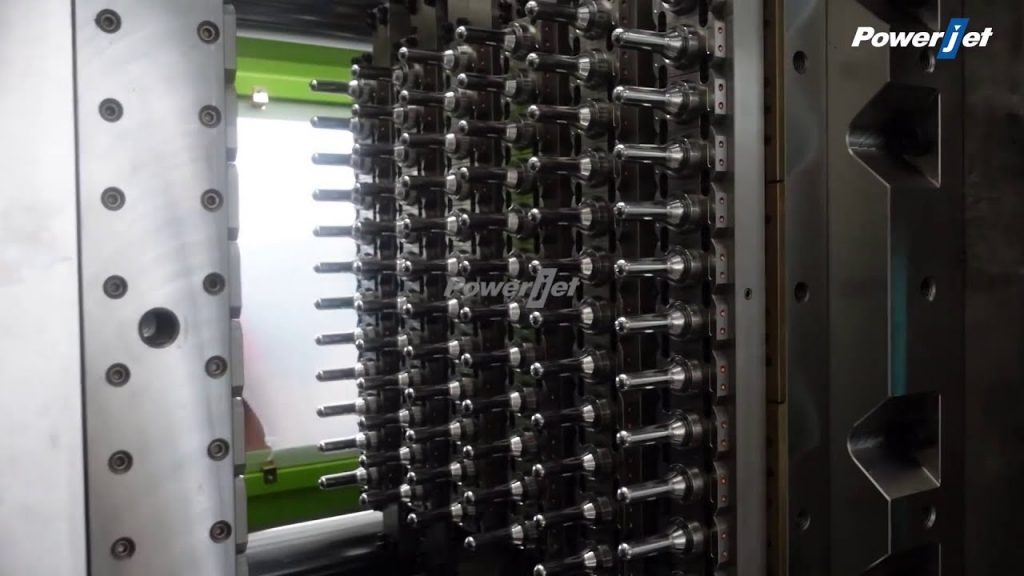

The PowerJet KPET3105L E6 is part of the PET Series, which is known for its exceptional performance and reliability. With 72 cavities, this machine allows for high-speed production, increasing your output and reducing cycle times. This means you can produce more preforms in less time, maximizing your productivity and profitability.

One of the key advantages of the PowerJet KPET3105L E6 is its advanced injection system. Equipped with a servo motor, this machine offers precise control over the injection process, ensuring consistent quality and accuracy. This results in uniform preforms with minimal variations, reducing waste and improving overall efficiency.

Additionally, the PowerJet KPET3105L E6 features a user-friendly interface and intuitive controls. This makes it easy to operate and allows for quick setup and changeover between different molds. With its ergonomic design and efficient workflow, this machine helps to streamline your production process and minimize downtime.

Furthermore, the PowerJet KPET3105L E6 is equipped with state-of-the-art automation technology. It includes a fully automatic preform handling system, which eliminates the need for manual intervention and reduces labor costs. This automation not only improves efficiency but also ensures consistent preform quality throughout the production run.

In terms of energy efficiency, the PowerJet KPET3105L E6 is designed to minimize power consumption. It incorporates energy-saving features such as variable-frequency drives and low-noise operation, reducing your energy costs and environmental impact. By choosing this machine, you can achieve sustainable manufacturing while maintaining high productivity.

To summarize, the PowerJet KPET3105L E6 with 72 cavities is the ultimate solution for PET preform injection molding. Its advanced technology, high efficiency, and user-friendly design make it the best choice for maximizing your return on investment. With this machine, you can enhance your production process, increase output, and achieve consistent preform quality.

Check the PET Series KPET3105L E6 from PowerJet today and revolutionize your plastic injection molding process. Your success starts with the right machine.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert URL] Plastic Injection Machine

"Efficient Injection Molding Machines for PET Preform Production: Unveiling the Powerjet KPET3105L E6 and High-Performance Plastic Molding Machine"