TAB Industries, LLC, based in Reading, PA, is revolutionizing the packaging industry with their fully automated TAB Wrapper Tornado orbital wrapping machine. This innovative machine offers a game-changing solution for securing and protecting palletized loads during transit. In this article, we will explore the benefits of the TAB Wrapper Tornado and how it can replace manual pallet wrapping, eliminate damage in transit, and improve overall efficiency.

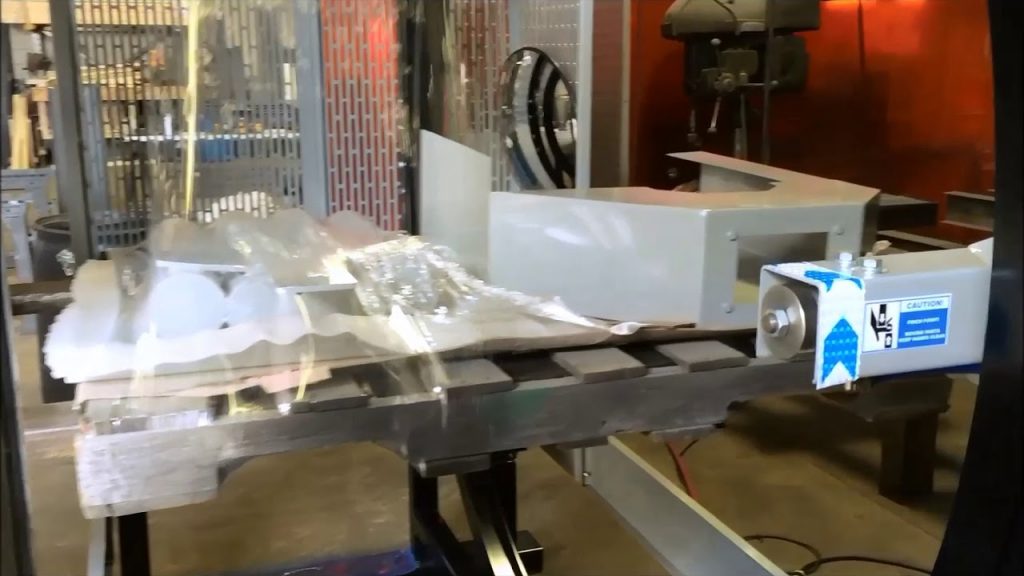

The TAB Wrapper Tornado is a state-of-the-art orbital pallet wrapper that utilizes advanced technology to securely wrap palletized loads with precision. This fully automated machine eliminates the need for manual labor, reducing the risk of injury and increasing productivity. With its user-friendly interface, operators can easily program the machine to wrap pallets of various sizes and shapes.

One of the key advantages of the TAB Wrapper Tornado is its ability to eliminate damage in transit. Traditional manual pallet wrapping methods often result in insufficient load containment, leading to damage during transportation. The TAB Wrapper Tornado ensures that the load is tightly wrapped and secured, minimizing the risk of product shifting or falling off the pallet. This not only reduces the chances of damage but also protects the integrity of the products, ensuring they arrive at their destination in pristine condition.

By using the TAB Wrapper Tornado, companies can significantly reduce their packaging costs. Manual pallet wrapping requires a significant amount of stretch film, which can be expensive. The TAB Wrapper Tornado optimizes the use of stretch film, reducing waste and saving money. Additionally, the machine operates at a high speed, allowing for faster wrapping cycles and increased throughput. This improved efficiency translates into cost savings and improved overall productivity.

The TAB Wrapper Tornado also offers a more environmentally friendly packaging solution. With its precise wrapping capabilities, the machine uses less stretch film, reducing plastic waste. This aligns with the growing demand for sustainable packaging solutions and helps companies reduce their environmental footprint.

In addition to its numerous benefits, the TAB Wrapper Tornado is also compatible with various industries and applications. Whether you are in the food and beverage, pharmaceutical, automotive, or construction industry, this machine can efficiently wrap and protect your palletized loads. Its versatility makes it an ideal choice for businesses of all sizes and industries.

In conclusion, the TAB Wrapper Tornado orbital wrapping machine from TAB Industries, LLC is a game-changer in the packaging industry. By replacing manual pallet wrapping and eliminating damage in transit, this machine offers a reliable and efficient solution for securing palletized loads. With its advanced technology, cost savings, and environmental benefits, the TAB Wrapper Tornado is the future of pallet wrapping. Check the coil packing solution with a leading manufacturer for the professional solution right here.

Keywords: Orbital Pallet Wrapper, TAB Industries, TAB Wrapper Tornado, automated wrapping machine, packaging industry, secure palletized loads, eliminate damage in transit, improve efficiency, user-friendly interface, reduce packaging costs, environmentally friendly, versatile. Orbital Stretch Wrapper

"Revolutionize Your Pallet Wrapping: Embrace the Efficiency of Automated Orbital Wrappers and Eliminate Transit Damage"