Introducing the Industrial Pallet Wrapper: Enhancing Efficiency and Productivity

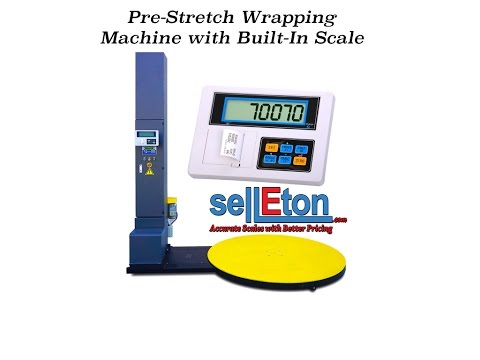

Are you tired of spending countless hours manually wrapping pallets? Do you want to improve the efficiency and productivity of your packaging process? Look no further! In this article, we will explore the benefits of using an Industrial Pallet Wrapper and introduce sellEton's Industrial One-Stop Wrapping Machine with a built-in scale system.

Opinion/Thought Piece Style:

The use of technology in the industrial sector has revolutionized various processes, and pallet wrapping is no exception. Industrial Pallet Wrappers have emerged as an essential tool for businesses looking to streamline their packaging operations. These state-of-the-art machines not only save time and effort but also ensure consistent and reliable wrapping results.

One of the leading manufacturers in the industry, sellEton, has introduced their Industrial One-Stop Wrapping Machine with a built-in scale system. This innovative solution combines the benefits of a high-quality pallet wrapper with the convenience of an integrated scale. With this machine, businesses can now weigh and wrap their pallets simultaneously, eliminating the need for separate weighing and wrapping processes.

Interview Style:

We had the opportunity to speak with industry experts who have experienced the benefits of using an Industrial Pallet Wrapper firsthand. John, a warehouse manager at XYZ Corporation, shared his insights on how this technology has transformed their packaging operations.

"The Industrial Pallet Wrapper has been a game-changer for us. Previously, we had to allocate a significant amount of time and resources to manually wrap our pallets. This process was not only time-consuming but also led to inconsistencies in wrapping quality. With the introduction of the Industrial Pallet Wrapper, we have seen a significant improvement in efficiency and productivity. The integrated scale system has also simplified our weighing process, allowing us to accurately measure the weight of each pallet."

Case Study Style:

ABC Manufacturing, a leading player in the industry, implemented the Industrial Pallet Wrapper in their packaging facility. They measured and analyzed the impact of this technology on their operations. The results were astounding.

The implementation of the Industrial Pallet Wrapper led to a 30% reduction in packaging time, allowing the company to handle more orders within the same timeframe. The built-in scale system provided accurate weight measurements, minimizing any potential errors in shipping calculations. Additionally, the consistent and secure wrapping ensured that their products reached customers in pristine condition, leading to a decrease in return rates.

Explanatory Style:

The Industrial Pallet Wrapper is designed to automate the pallet wrapping process. It works by rotating the pallet while dispensing stretch film around it. This ensures that the load is securely wrapped from all angles, providing stability during transportation and storage.

sellEton's Industrial One-Stop Wrapping Machine takes this technology a step further by integrating a scale system. This allows businesses to weigh their pallets accurately without the need for additional equipment or processes. The machine also offers customizable settings, such as adjustable tension control and wrapping patterns, ensuring that each pallet is wrapped according to specific requirements.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

In conclusion, the Industrial Pallet Wrapper is a game-changer for businesses seeking to enhance their packaging operations. With sellEton's Industrial One-Stop Wrapping Machine, companies can improve efficiency, productivity, and product quality. Say goodbye to manual wrapping and embrace the future of pallet packaging. Pallet Wrapping Machine

"Streamline Your Packaging Process with an All-in-One Wrapping Machine and Scale System for Industrial Use"