Check out the video where Osaro CEO, Derik Pridmore, discusses industrial robotics and deep reinforcement learning at the O'Reilly 2017 Artificial Intelligence conference. In this article, we will delve into the key points covered in the video and explore the significance of industrial robotics and deep reinforcement learning in the manufacturing industry. Let's dive in!

Title: Exploring the Future of Industrial Robotics and Deep Reinforcement Learning

Introduction:

Industrial robotics has revolutionized the manufacturing sector, driving efficiency, precision, and productivity to new heights. However, with the emergence of deep reinforcement learning, the potential of industrial robotics has expanded even further. In this article, we will explore the insights shared by Derik Pridmore, CEO of Osaro, as he discusses the intersection of industrial robotics and deep reinforcement learning at the O'Reilly 2017 Artificial Intelligence conference.

I. The Rise of Industrial Robotics:

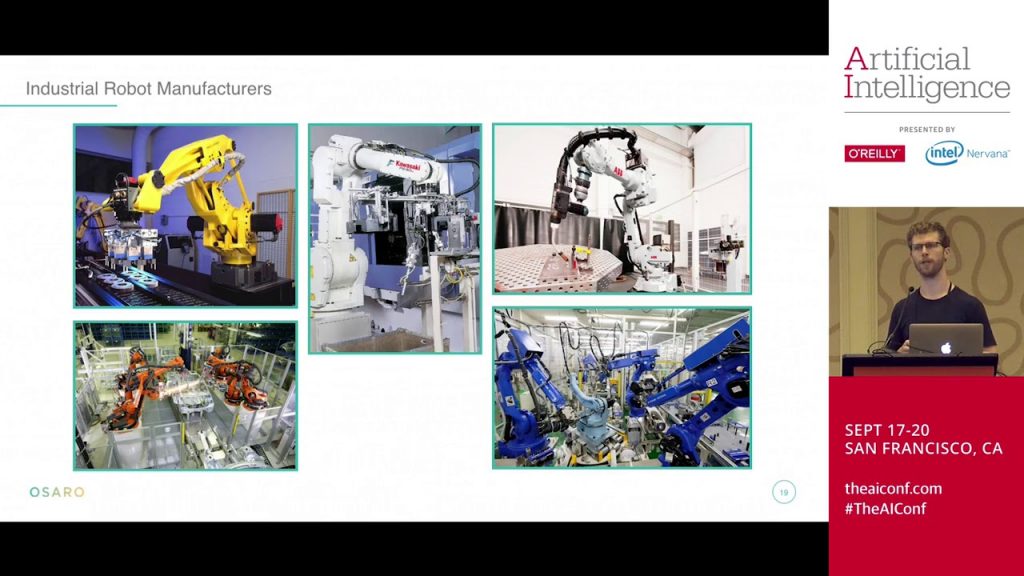

Industrial robot manufacturers have played a crucial role in transforming the manufacturing landscape. These companies have developed advanced robots capable of performing complex tasks with high accuracy and speed. The integration of robotics has not only improved production quality but also enhanced workplace safety by replacing humans in hazardous or repetitive tasks.

II. Understanding Deep Reinforcement Learning:

Deep reinforcement learning takes industrial robotics to the next level by enabling robots to learn and adapt to their environment through trial and error. This technology combines deep learning algorithms with reinforcement learning principles, allowing robots to make decisions based on continuous feedback and rewards. As a result, robots become more autonomous, capable of handling dynamic scenarios, and performing tasks that were previously considered too challenging.

III. Derik Pridmore's Insight:

During his talk at the O'Reilly 2017 Artificial Intelligence conference, Derik Pridmore shed light on the potential of deep reinforcement learning in the industrial robotics domain. He emphasized that this technology enables robots to learn from their mistakes and improve their performance over time. Pridmore also highlighted the significance of real-time decision-making capabilities in industrial settings, where robots need to adapt quickly to changing conditions.

IV. The Impact on Industrial Robot Manufacturers:

Industrial robot manufacturers are embracing deep reinforcement learning to enhance the capabilities of their robots. By leveraging this technology, manufacturers can automate complex tasks that were previously only feasible for skilled human operators. This not only reduces labor costs but also increases production efficiency and consistency. Manufacturers can now rely on intelligent robots that continuously learn and optimize their performance.

V. The Future of Industrial Robotics:

As technology continues to evolve, the future of industrial robotics looks promising. Deep reinforcement learning holds immense potential in enabling robots to perform intricate tasks with minimal human intervention. This advancement will further revolutionize industries such as automotive, electronics, and healthcare, where precision and efficiency are paramount.

VI. Conclusion:

Derik Pridmore's discussion on industrial robotics and deep reinforcement learning highlights the growing significance of this technology in the manufacturing industry. Industrial robot manufacturers are embracing deep reinforcement learning to enhance the capabilities of their robots, leading to increased productivity, improved safety, and cost savings. As we look towards the future, the integration of deep reinforcement learning in industrial robotics will undoubtedly shape the way we manufacture and automate processes.

Check the coil packing solution with leading manufacturers for professional solutions just here: [insert relevant call-to-action or link] Industrial Robot

"Exploring the Synergy Between Industrial Robotics and Deep Reinforcement Learning: Enhancing Efficiency and Automation in Manufacturing"