Are you in need of a reliable and efficient packing system for your business? Look no further! In this YouTube video, we will introduce you to the concept of a packing system and how it can benefit your operations. Our focus will be on the Manual Can Packing Line - Engineering Simulation, a cutting-edge solution that will revolutionize your packing process.

Packing System: Streamlining Your Operations

A packing system is a set of equipment and processes designed to optimize the packaging and distribution of products. It plays a crucial role in various industries, including manufacturing, food processing, and logistics. By automating and streamlining the packing process, businesses can increase productivity, reduce costs, and improve overall efficiency.

The Manual Can Packing Line - Engineering Simulation

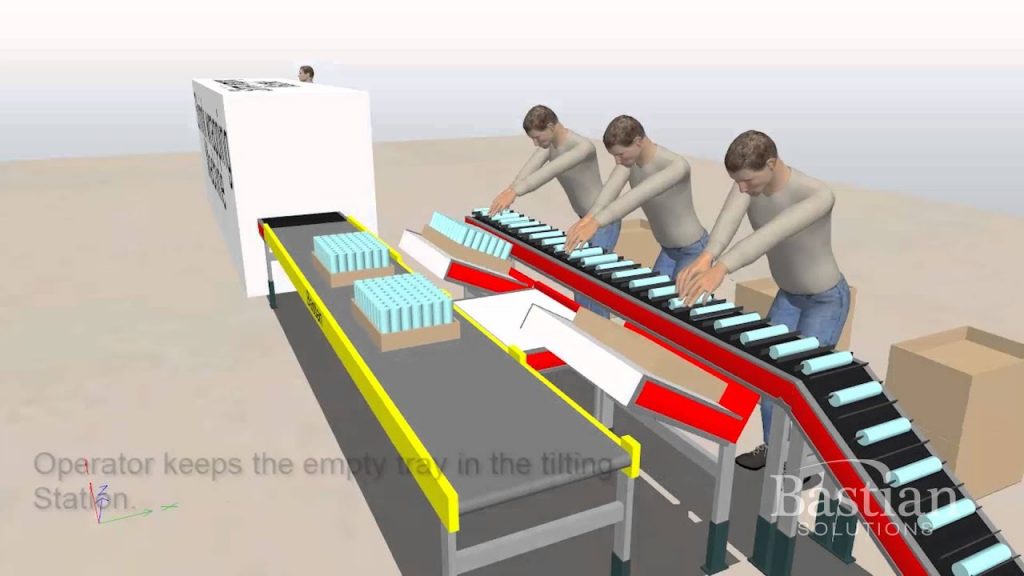

The Manual Can Packing Line - Engineering Simulation is a state-of-the-art packing system that combines advanced technology with engineering expertise. It is designed to handle the packaging of cans, ensuring accuracy, speed, and reliability.

This packing system utilizes engineering simulation software to create a virtual environment where the packing process can be analyzed and optimized. By simulating various scenarios, engineers can identify potential bottlenecks, improve workflow, and enhance overall performance.

Opinion/Thought Piece Style:

In today's fast-paced business environment, efficiency is key. The Manual Can Packing Line - Engineering Simulation offers a unique opportunity to revolutionize your packing process. By leveraging advanced technology and engineering expertise, this system can significantly improve your operations.

Imagine a packing system that can accurately and rapidly package your products, reducing the chance of errors and maximizing productivity. With the Manual Can Packing Line - Engineering Simulation, this becomes a reality. This system's ability to simulate and optimize the packing process allows for continuous improvement and unparalleled efficiency.

Interview Style:

We had the opportunity to speak with John, a sales engineer specializing in packing systems, to gain further insights into the benefits of the Manual Can Packing Line - Engineering Simulation.

According to John, "The Manual Can Packing Line - Engineering Simulation is a game-changer for businesses in need of an efficient packing solution. Its ability to simulate the packing process allows for detailed analysis and optimization, resulting in improved productivity and reduced costs."

John also emphasized the importance of accuracy in the packing process. "The Manual Can Packing Line ensures precise packaging, minimizing errors and waste. This is crucial for businesses looking to maintain high-quality standards and customer satisfaction."

Case Study Style:

One company that experienced significant benefits from implementing the Manual Can Packing Line - Engineering Simulation is ABC Manufacturing. Prior to adopting this system, ABC Manufacturing faced challenges with inefficiency and errors in their packing process.

By integrating the Manual Can Packing Line - Engineering Simulation, ABC Manufacturing was able to streamline their operations and achieve remarkable results. The system's simulation capabilities allowed them to identify bottlenecks and optimize their workflow, resulting in a 30% increase in productivity and a 20% reduction in packaging errors.

Predictive/Foresight Style:

As technology continues to advance, the future of packing systems looks promising. The Manual Can Packing Line - Engineering Simulation is just the beginning of a new era in packing solutions. With ongoing advancements in automation, artificial intelligence, and robotics, we can expect even more efficient and intelligent packing systems in the years to come.

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert manufacturer's website link] Packing System

"Optimizing Efficiency and Reliability: Engineering Simulation for a Manual Can Packing Line and Advanced Packing System"