Check out our website for more information on Industrial Robot Programming and how it can revolutionize your manufacturing process."

Title: Enhancing Manufacturing Efficiency with Industrial Robot Programming

Introduction:

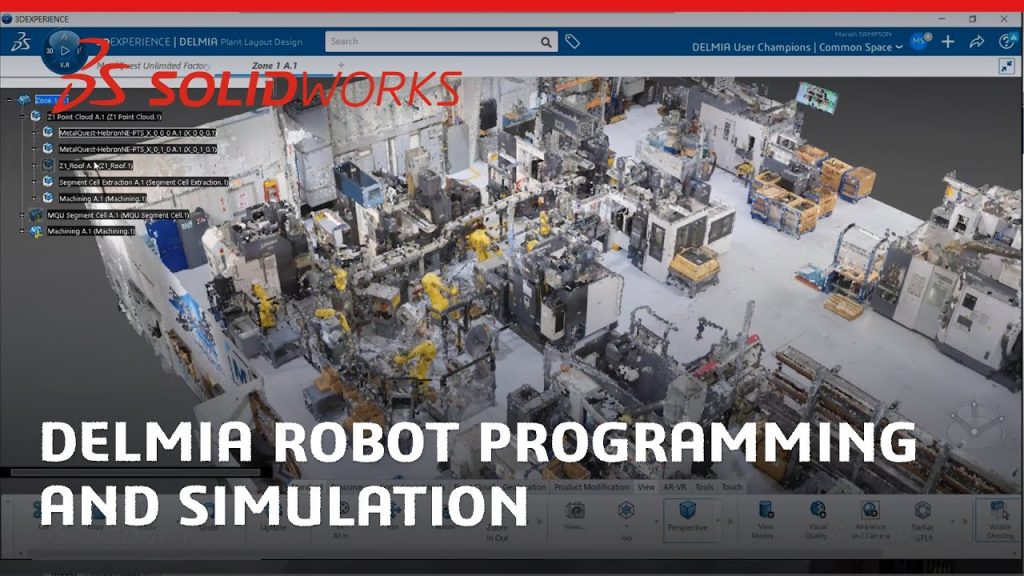

In today's rapidly evolving manufacturing landscape, the role of industrial robots has become increasingly crucial. These advanced machines have the potential to streamline processes, increase productivity, and optimize overall efficiency. Mariah Sampson, a renowned DELMIA Industry Process Consultant, recently showcased the power of Industrial Robot Programming at Manufacturing Day held at MetalQuest Unlimited. In this article, we will delve into the fascinating world of Industrial Robot Programming and its impact on the manufacturing industry.

Opinion/Thought Piece Style:

Industrial Robot Programming: Unleashing the Power of Automation

By [Your Name]

Automation has become the cornerstone of modern manufacturing, with industrial robots taking center stage. These programmable machines have revolutionized the industry by providing manufacturers with the ability to automate complex tasks and improve overall productivity. Mariah Sampson, a DELMIA Industry Process Consultant, recently demonstrated the potential of Industrial Robot Programming at MetalQuest Unlimited's Manufacturing Day.

Industrial Robot Programming offers a wide range of benefits that can significantly enhance manufacturing efficiency. By programming robots to perform repetitive tasks, manufacturers can reduce the risk of errors and ensure consistent quality. This not only improves product reliability but also helps companies meet demanding production deadlines.

During the event, Sampson showcased how Industrial Robot Programming can optimize various manufacturing processes, including assembly, welding, and material handling. By using advanced simulation software from DELMIA, she demonstrated how robots can be programmed to perform these tasks with precision and accuracy.

The ability to simulate robot movements and test them virtually before implementation is a game-changer. It minimizes the risk of costly errors and allows manufacturers to optimize their production lines efficiently. With DELMIA's Robot Programming and Simulation, manufacturers can visualize and validate their robot programs, eliminating the need for time-consuming trial and error methods.

Industrial Robot Programming also empowers manufacturers to adapt quickly to changing market demands. By reprogramming robots, businesses can easily switch between different product lines and efficiently handle product customization requests. This flexibility ensures that manufacturers can stay competitive in an ever-changing market.

The integration of Industrial Robot Programming with other technologies, such as artificial intelligence and machine learning, further enhances manufacturing capabilities. Robots can now learn from previous tasks and adapt their programming accordingly, improving efficiency and reducing the need for constant human intervention.

In conclusion, Industrial Robot Programming is a game-changer for the manufacturing industry. Mariah Sampson's demonstration at MetalQuest Unlimited showcased the immense potential of this technology in enhancing efficiency, productivity, and adaptability. By harnessing the power of advanced simulation software and embracing automation, manufacturers can unlock new levels of success in today's competitive landscape.

Check the Industrial Robot Programming solutions with leading manufacturers for a professional and efficient manufacturing process. Industrial Robot

"Mastering Robot Programming and Simulation for Industrial Automation: Unlocking Efficiency and Precision in DELMIA and Beyond"