Are you interested in learning about the advancements in industrial robot applications? In this video, we will explore the challenges faced by traditional industrial robots in achieving high-speed motion with high accuracy. We will also discuss the concept of dynamic compensation and its role in the development of next-generation industrial robots.

Traditionally, industrial robots have struggled to achieve both high-speed motion and high accuracy. This is primarily due to their large dynamical characteristics, which limit their ability to perform precise tasks at high speeds. However, recent advancements in technology have paved the way for the development of more efficient and accurate industrial robots.

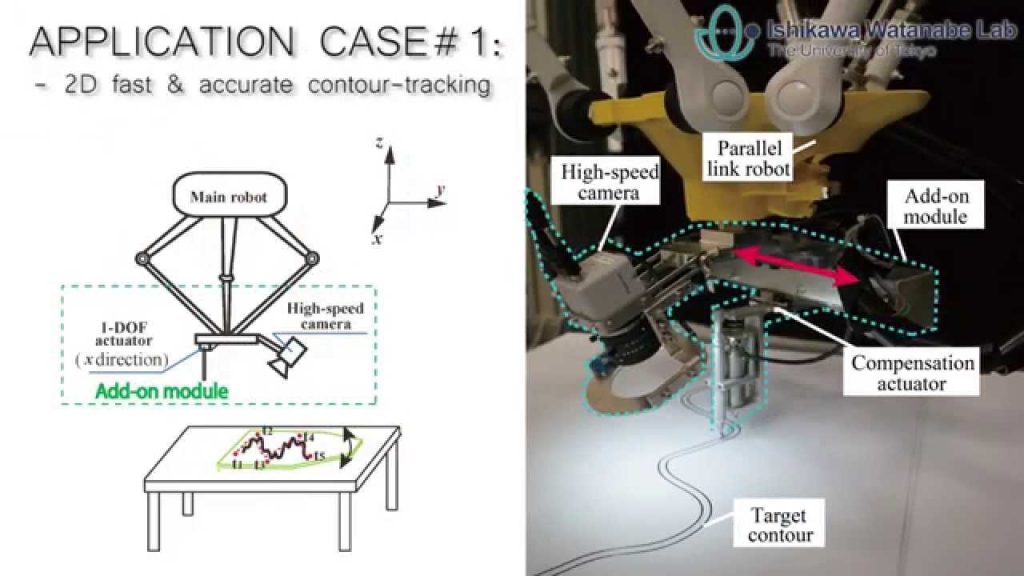

One of the key factors contributing to the improved performance of industrial robots is dynamic compensation. By implementing advanced control algorithms and feedback systems, industrial robots can now compensate for the dynamic disturbances that occur during high-speed motion. This allows them to achieve both speed and accuracy, making them ideal for a wide range of applications.

Industrial robot applications have witnessed significant growth in various industries. From manufacturing and automotive to healthcare and logistics, industrial robots have revolutionized the way tasks are performed. They can handle repetitive and labor-intensive tasks with precision and efficiency, leading to increased productivity and reduced costs.

In the manufacturing industry, industrial robots are widely used for tasks such as assembly, welding, and material handling. They can perform these tasks with high accuracy and speed, resulting in improved product quality and reduced production time. Industrial robots have also found applications in the automotive industry, where they assist in assembly line operations and improve overall efficiency.

The healthcare industry has also benefited from the use of industrial robots. They are used in surgeries, rehabilitation, and patient care, providing precise and controlled movements that enhance the quality of medical procedures. In logistics, industrial robots play a crucial role in warehouse automation, streamlining order fulfillment processes, and optimizing inventory management.

As industrial robot applications continue to evolve, the next-generation of industrial robots is expected to bring even more advanced features and capabilities. These robots will be equipped with enhanced sensing and perception abilities, allowing them to interact more intelligently with their environment. They will also have improved mobility and adaptability, enabling them to handle complex tasks and operate in diverse settings.

In conclusion, industrial robot applications have transformed various industries by offering high-speed motion with high accuracy. The integration of dynamic compensation techniques has further improved their performance, making them indispensable in manufacturing, automotive, healthcare, and logistics sectors. As technology continues to advance, the next-generation of industrial robots holds great promise for even more impressive applications.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

"Unleashing the Potential: Advancements in Dynamic Compensation for Next-Generation Industrial Robots and Their Applications"