Title: Industrial Handling Equipment: Streamlining Material Handling Processes

Description:

Introduction:

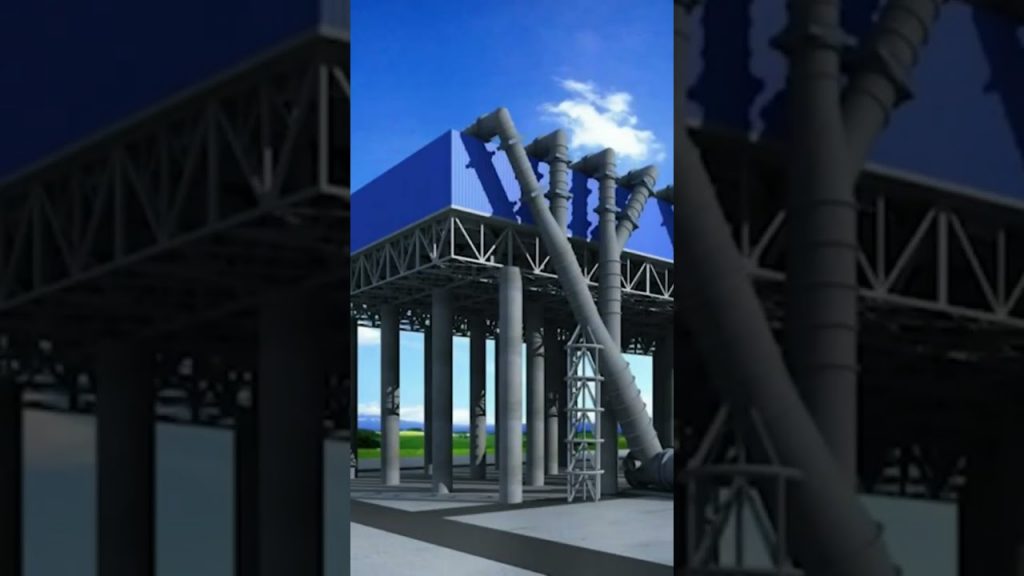

Discover the world of industrial handling equipment and gain valuable insights into the efficient management of material handling processes. In this video, we delve into the key aspects of Industrial Handling Equipment, providing a comprehensive overview of its importance, benefits, and operational procedures.

Video Content:

Our video explores the intricacies of Industrial Handling Equipment, shedding light on the various types and their specific applications. We highlight the significance of utilizing the right equipment to optimize material handling processes, ultimately enhancing productivity and reducing operational costs.

Key Highlights:

1. Understanding Industrial Handling Equipment:

- Explore the wide range of equipment used in industrial settings, including forklifts, conveyors, pallet jacks, and more.

- Uncover how each type of equipment plays a crucial role in streamlining material handling tasks.

2. Benefits of Industrial Handling Equipment:

- Learn about the advantages of using specialized equipment, such as improved efficiency, enhanced safety, and increased profitability.

- Discover how these benefits contribute to a more streamlined workflow and improved overall operations.

3. Operational Steps:

- Gain valuable insights into the step-by-step process of utilizing industrial handling equipment.

- From equipment inspection and maintenance to proper handling techniques, we cover it all to ensure safe and effective operation.

Call to Action:

If you found this video informative and valuable, we invite you to like, subscribe, and share it with others who may benefit from this knowledge. Stay tuned for more insightful content on industrial handling equipment and material handling processes.

Additional Tags and Keywords:

Industrial Handling Equipment, material handling equipment, material handling processes, forklifts, conveyors, pallet jacks, industrial equipment, workflow optimization, operational efficiency, workplace safety, productivity enhancement, equipment inspection, equipment maintenance.

Hashtags:

#IndustrialHandlingEquipment #MaterialHandlingProcesses #WorkflowOptimization #ProductivityEnhancement #WorkplaceSafety

Title: Efficient Material Handling Equipment Process Tilter

Introduction:

A material handling equipment process tilter is an essential tool in various industries, as it enables the safe and efficient movement of heavy materials and goods. This tilter is designed to enhance productivity, reduce manual labor, and ensure the safety of workers. In this article, we will outline the key features and benefits of an efficient material handling equipment process tilter.

1. Heavy-Duty Construction:

An efficient tilter for material handling equipment should be built with a sturdy and durable construction. It should be capable of withstanding heavy loads and extended use without compromising its structural integrity. A robust frame, reinforced components, and high-quality materials are essential for ensuring longevity and reliability.

2. Versatility:

The tilter should offer versatile functionality to accommodate a wide range of materials, shapes, and sizes. Adjustable features such as tilt angle, rotation, and height adjustment should be present to cater to different handling requirements. This versatility enables the tilter to handle various loads efficiently, increasing productivity and reducing the need for multiple equipment types.

3. Easy Operation:

An efficient tilter should be user-friendly and easy to operate. It should feature intuitive controls and ergonomic design, allowing operators to handle the equipment with minimal effort and training. Clear instructions, safety features, and easy maintenance procedures should be provided to ensure smooth operations and prevent accidents.

4. Safety Measures:

Safety is paramount in any material handling process. An efficient tilter should be equipped with safety features such as load holding devices, non-slip surfaces, and emergency stop functions. Additionally, it should comply with industry safety standards and regulations to ensure the well-being of operators and prevent material damage.

5. Energy Efficiency:

In today's environmentally conscious world, an efficient tilter should be designed to minimize energy consumption. Energy-efficient motors, power-saving features, and intelligent control systems can significantly reduce electricity usage, leading to cost savings and a reduced carbon footprint.

6. Maintenance and Durability:

The tilter should be designed for easy maintenance, with readily accessible components and minimal downtime required for repairs. Regular maintenance procedures should be outlined to ensure the longevity and optimal performance of the equipment. Additionally, the tilter should come with a warranty and after-sales support to address any potential issues.

Conclusion:

An efficient material handling equipment process tilter plays a crucial role in optimizing productivity and ensuring safety in various industries. By focusing on heavy-duty construction, versatility, ease of operation, safety measures, energy efficiency, and maintenance, businesses can select a tilter that meets their specific needs. Investing in a high-quality tilter will enhance material handling processes, reduce labor costs, and improve overall operational efficiency.Handling Machine

#material #handling #equipment #process