Check out Bulk Automation Ltd for the most efficient and reliable manual bagging packaging system with ABB robot palletising system. This cutting-edge technology will revolutionize your packaging process and streamline your operations. Read on to discover how this innovative solution can benefit your business.

Introduction:

In today's fast-paced world, businesses are constantly looking for ways to improve their efficiency and productivity. One area where significant improvements can be made is in the packaging process. Manual bagging and palletising can be time-consuming and labor-intensive. That's where Bulk Automation Ltd comes in with their state-of-the-art manual bagging packaging system with ABB robot palletising system.

Opinion/Thought Piece Style:

In this article, we will explore the benefits of using Bulk Automation Ltd's manual bagging packaging system with ABB robot palletising system. We will delve into the features and advantages of this technology, highlighting how it can revolutionize your packaging operations and improve your bottom line.

Explanatory Style:

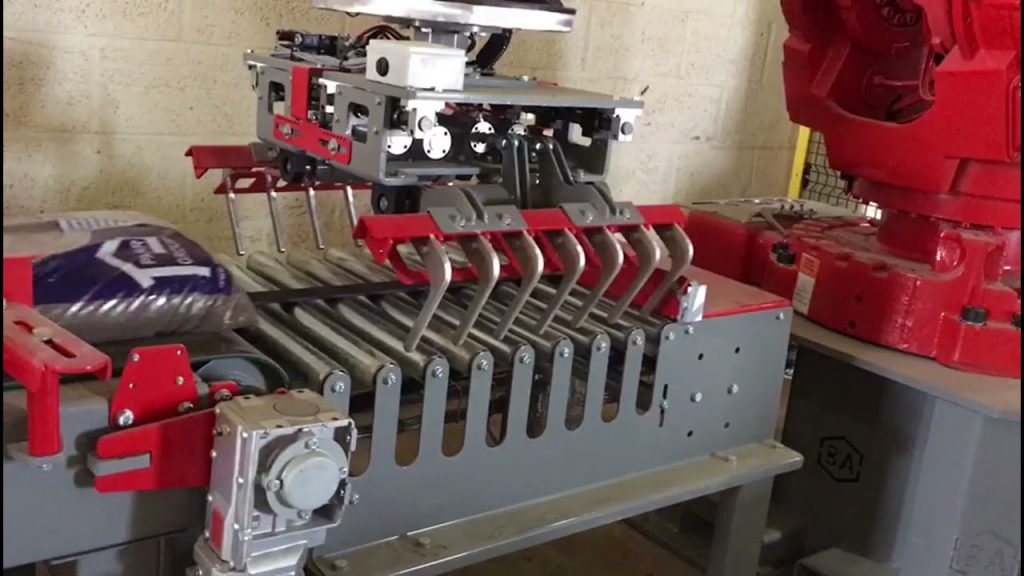

The manual bagging packaging system from Bulk Automation Ltd is designed to streamline and automate the packaging process. With this system, you can eliminate the need for manual bagging, reducing the risk of human error and increasing overall productivity. The ABB robot palletising system adds another layer of efficiency by automating the palletising process, ensuring accurate and consistent stacking.

Case Study Style:

To truly understand the benefits of the manual bagging packaging system with ABB robot palletising system, let's take a look at a real-life example. Company X, a leading manufacturer in the food industry, was facing challenges in their packaging process. They were using a manual bagging system that required a significant amount of time and resources. This was causing delays in their production line and impacting their overall efficiency.

Predictive/Foresight Style:

Company X decided to invest in the manual bagging packaging system with ABB robot palletising system from Bulk Automation Ltd. They recognized the potential for this technology to transform their packaging process and improve their operations. After implementing the system, Company X experienced a significant increase in productivity and efficiency. The manual bagging process was automated, reducing the need for manual labor and minimizing the risk of errors. The ABB robot palletising system ensured accurate and efficient stacking, optimizing their warehouse space.

In-depth Analysis Style:

The manual bagging packaging system with ABB robot palletising system offers numerous benefits for businesses in various industries. It provides a cost-effective solution that reduces labor costs and increases overall productivity. The automation of the bagging process ensures consistency and accuracy, eliminating the risk of human error. Additionally, the ABB robot palletising system optimizes warehouse space by stacking products in an efficient and organized manner.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

Conclusion:

In conclusion, the manual bagging packaging system with ABB robot palletising system from Bulk Automation Ltd is a game-changer for businesses looking to streamline their packaging process. By automating the bagging and palletising processes, this technology improves efficiency, reduces labor costs, and ensures accurate and consistent stacking. If you're looking to enhance your packaging operations, look no further than Bulk Automation Ltd's manual bagging packaging system with ABB robot palletising system. Packing System

"Efficient Manual Bagging and ABB Robot Palletising System: Streamlining Packaging with Used Packing System"