Title: Packaging Line Automation - Streamlining Efficiency and Enhancing Productivity | OAL Case Study

Description:

Welcome to our comprehensive case study on Packaging Line Automation, focusing on the successful implementation of this cutting-edge technology at Wealmoor. In this video, we delve into the transformative power of automated packaging systems, exploring how they revolutionize the manufacturing industry and optimize operational processes. Discover how Wealmoor, a leading player in the industry, harnessed the potential of Packaging Line Automation to significantly enhance their productivity and streamline their operations.

Introduction:

In this captivating video, we explore the remarkable benefits and advancements brought about by Packaging Line Automation. Witness how Wealmoor leveraged this innovative solution to overcome challenges and achieve remarkable results. Unlock the potential of automation and witness a paradigm shift in the packaging industry.

Video Content:

1. Enhancing Efficiency and Productivity: Discover how Packaging Line Automation has revolutionized Wealmoor's operations, enabling them to handle larger volumes with increased speed and accuracy. Learn about the various automated processes that have eliminated bottlenecks and reduced downtime, ultimately leading to enhanced efficiency.

2. Streamlining Quality Control: Dive into the intricacies of automated quality control systems implemented by Wealmoor. Explore how cutting-edge technology ensures consistent product quality, reduced errors, and compliance with industry standards. Witness how automated inspections and data analysis have revolutionized the quality assurance process.

3. Optimizing Resource Utilization: Gain insights into how Packaging Line Automation has optimized resource allocation and utilization at Wealmoor. Learn about intelligent algorithms that optimize production schedules, minimize waste, and maximize the utilization of manpower and materials.

4. Ensuring Flexibility and Adaptability: Discover how Wealmoor's automated packaging line caters to a wide range of products, from different shapes and sizes to varying packaging requirements. Witness the seamless transition from one product to another without compromising on efficiency.

5. Enhancing Workplace Safety: Learn about the safety features and protocols integrated into automated packaging systems, ensuring a secure working environment for Wealmoor's employees. Explore how these systems mitigate risks and adhere to stringent safety standards.

Call to Action:

If you found this video informative and insightful, please consider liking, subscribing, and sharing it with your peers. Stay updated with the latest advancements in Packaging Line Automation by subscribing to our channel.

Additional Tags and Keywords:

Packaging Line Automation, automated packaging systems, Wealmoor, OAL Case Study, manufacturing industry, operational processes, efficiency, productivity, quality control, resource utilization, workplace safety, automated inspections, data analysis, flexibility, adaptability, optimized production schedules, waste reduction.

Hashtags:

#PackagingLineAutomation #AutomationRevolution #WealmoorSuccessStory #OperationalEfficiency #QualityControl #ResourceUtilization #WorkplaceSafety #ManufacturingAdvancements

Title: Revolutionizing Packaging Line Efficiency: Wealmoor's Automation Journey - A OAL Case Study

Introduction:

In this case study, we delve into the transformative journey of Wealmoor, a leading packaging company, as they partnered with OAL, a pioneering automation solutions provider. We explore how Wealmoor implemented an innovative tilter system, revolutionizing their packaging line efficiency and optimizing their operations. This case study highlights the tangible benefits, challenges, and lessons learned from this successful collaboration.

1. Background:

1.1 Wealmoor's packaging line challenges

1.2 OAL's expertise in automation solutions

2. Goals and Objectives:

2.1 Enhancing productivity and reducing labor costs

2.2 Ensuring product safety and minimizing waste

2.3 Streamlining packaging line processes

3. Solution:

3.1 Introduction of the tilter system in Wealmoor's packaging line

3.2 Integration of OAL's proprietary software and hardware

3.3 Customization and adaptation to meet Wealmoor's specific requirements

4. Implementation Process:

4.1 Detailed planning and scoping

4.2 Collaborative approach and seamless integration

4.3 Training and onboarding for Wealmoor's staff

5. Benefits and Results:

5.1 Drastic reduction in labor costs and increased productivity

5.2 Enhanced product safety and minimized waste

5.3 Streamlined packaging line, leading to faster throughput

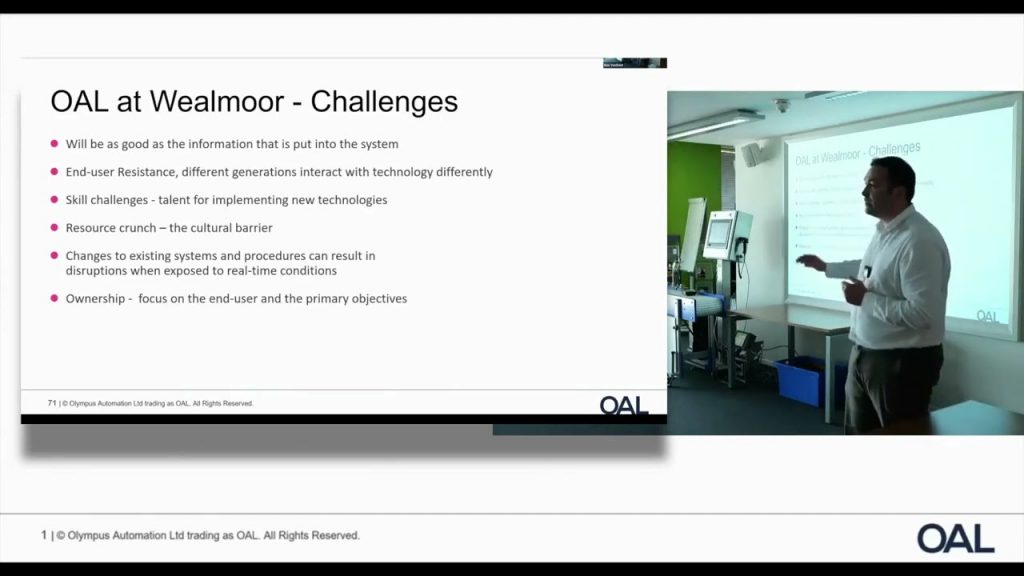

6. Challenges and Lessons Learned:

6.1 Overcoming initial resistance to change

6.2 Ensuring smooth transition and minimal disruption

6.3 Continuous monitoring and maintenance for optimal performance

7. Conclusion:

Through their collaboration with OAL and the successful implementation of the tilter system, Wealmoor achieved remarkable improvements in their packaging line efficiency. The transformational journey not only provided tangible benefits but also highlighted the importance of strategic planning, customization, and ongoing support in automation initiatives. Wealmoor's experience serves as an inspirational case study for other packaging companies seeking to optimize their operations and embrace automation. Automatic Packing Line

#Wealmoor #Packaging #Line #Automation #OAL #Case #Study