Check out our video on Lynch Metals' state-of-the-art liquid foam packaging process, which ensures the safety of all products during shipment. In this article, we will dive deeper into the process and explain how it works in detail. Whether you are a business owner looking for a reliable packing solution or simply curious about the technology behind it, this article will provide you with valuable insights.

Liquid foam packaging has revolutionized the way products are protected during transportation. Traditional packing methods often involve using materials such as bubble wrap or Styrofoam, which can be bulky and ineffective in providing adequate protection. Lynch Metals recognized the need for a more advanced solution and developed a cutting-edge liquid foam packaging process.

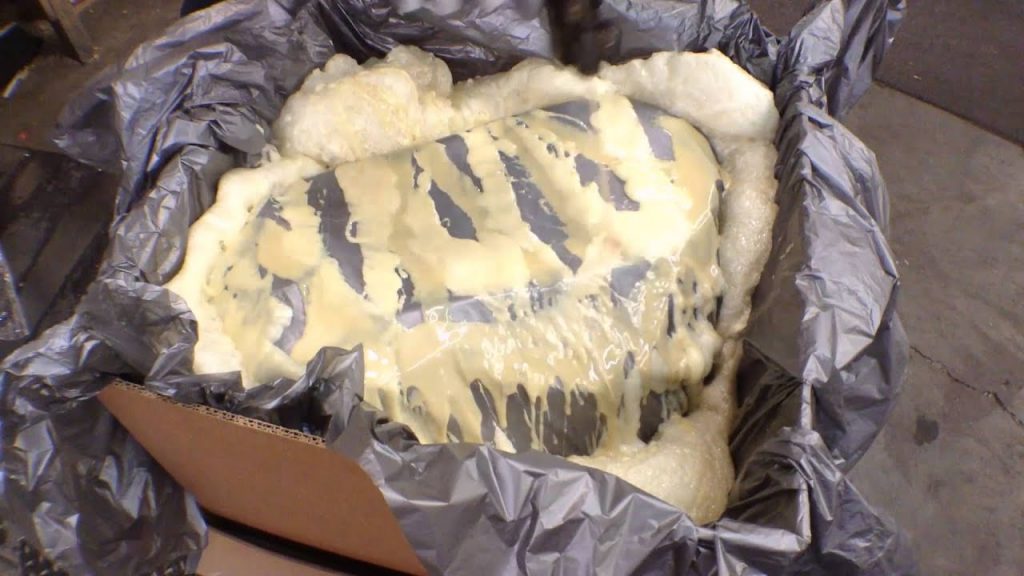

The first step in this process involves the use of a specially designed machine, known as the Used Packing System. This system is equipped with state-of-the-art technology that allows for precise control of the foam application. The foam is dispensed in a liquid form, which then expands to fill every nook and cranny of the packaging, creating a custom-fit protective layer around the product.

One of the key advantages of the Used Packing System is its versatility. It can be used to package a wide range of products, regardless of size or shape. This makes it an ideal solution for businesses that deal with various types of goods. Whether you are shipping delicate electronic devices or heavy machinery, the Used Packing System can ensure that your products arrive at their destination in pristine condition.

In addition to its versatility, the liquid foam packaging process offers several other benefits. Firstly, the foam itself is lightweight, which helps to minimize shipping costs. Traditional packing materials can add significant weight to the overall package, resulting in higher shipping fees. With liquid foam packaging, businesses can save on transportation expenses without compromising on product protection.

Furthermore, the foam used in this process is environmentally friendly. Unlike traditional materials that are difficult to recycle, the foam can be easily disposed of and reused. This aligns with Lynch Metals' commitment to sustainability and reduces the company's carbon footprint.

The liquid foam packaging process also provides excellent shock absorption. The foam molds itself around the product, creating a cushioning effect that absorbs any impacts during transportation. This ensures that even fragile items remain intact and undamaged, regardless of the conditions they may encounter along the way.

In summary, Lynch Metals' state-of-the-art liquid foam packaging process, powered by the Used Packing System, offers a superior solution for product protection during shipment. Its versatility, lightweight nature, environmental friendliness, and shock absorption capabilities make it the ideal choice for businesses in various industries.

If you are interested in exploring the benefits of liquid foam packaging further or are in need of a professional packing solution, we invite you to check out the leading manufacturer's website for more information. They offer a wide range of packaging solutions tailored to meet your specific needs. Don't compromise on the safety of your products during shipment - trust the experts in the field. Packing System

"Efficient and Sustainable Packaging: Discover the Liquid Foam Packaging Process and Eco-Friendly Packing System"