"Check out the top-notch Filling and Sealing Machine for all your liquid and semisolid packaging needs. With its unbeatable reliability and cost-effectiveness, this machine is the ultimate solution for efficient packaging. In this article, we will delve into the Blow-Fill-Seal process and explore the 3D visualization of the bottlepack bottling plant. So, let's dive right in!"

Introduction:

When it comes to packaging liquids and semisolids, there's no better way than using a high-quality Filling and Sealing Machine. This advanced technology ensures that your products are efficiently packaged, maintaining their quality and freshness. In this article, we will take a closer look at the revolutionary Blow-Fill-Seal process and explore the 3D visualization of a cutting-edge bottlepack bottling plant.

Blow-Fill-Seal Process:

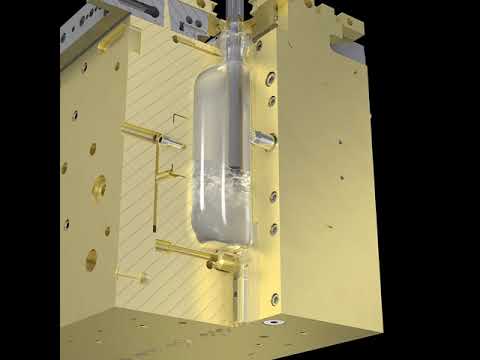

The Blow-Fill-Seal process is a highly efficient method of packaging liquids and semisolids. It involves three main steps: blow molding, filling, and sealing. First, the container is formed by blowing air into a parison, creating the desired shape. Then, the product is precisely filled into the container, ensuring accurate quantities. Finally, the container is hermetically sealed, guaranteeing product integrity and preventing any leakage or contamination.

Why Choose a Filling and Sealing Machine?

There are several reasons why a Filling and Sealing Machine is the best choice for your packaging needs. Firstly, these machines offer unparalleled reliability. With their advanced technology and precise engineering, they ensure consistent and efficient packaging, reducing the risk of errors or downtime. This reliability translates into increased productivity and customer satisfaction.

Secondly, Filling and Sealing Machines are extremely cost-effective. By automating the packaging process, they eliminate the need for manual labor, saving both time and money. Additionally, these machines optimize the use of packaging materials, reducing waste and minimizing costs in the long run.

Furthermore, these machines are versatile and adaptable to various industries. Whether you need to package pharmaceuticals, food and beverages, cosmetics, or any other liquid or semisolid product, a Filling and Sealing Machine can be tailored to meet your specific requirements. Its flexibility ensures that your packaging process is efficient and tailored to your product's needs.

3D Visualization of a Bottlepack Bottling Plant:

Imagine being able to visualize the entire packaging process in a three-dimensional space. With the 3D visualization of a bottlepack bottling plant, you can do just that! This cutting-edge technology allows you to explore every aspect of the packaging line, from the Blow-Fill-Seal process to the final product. This visualization not only enhances your understanding of the packaging process but also provides valuable insights for optimizing efficiency and productivity.

Conclusion:

When it comes to packaging liquids and semisolids, a Filling and Sealing Machine is the ultimate solution. Its reliability, cost-effectiveness, and versatility make it the preferred choice for numerous industries. Additionally, the 3D visualization of a bottlepack bottling plant adds a whole new dimension to understanding and optimizing the packaging process.

So, if you're searching for a top-notch Filling and Sealing Machine, look no further. Check out leading manufacturers in the industry who can provide you with the professional solution you need. Invest in this innovative technology and watch your packaging process soar to new heights of efficiency and success.

Check the coil packing solution with leading manufacturers for the professional solution just here. Filling Packing Machine

"Efficient Blow-Fill-Seal Process Unveiled: 3D Visualization of Bottlepack Bottling Plant and Advanced Filling & Sealing Machine"