Check out the leading manufacturers for professional coil packing solutions here:"

Title: Creating Vibrant 2 Colour Combs with Plastic Injection Molding Machines

Introduction:

In the world of fashion and personal grooming, hair accessories play a significant role in enhancing one's style and appearance. Among these accessories, the 2 Colour Comb stands out with its unique design and versatility. This article explores the process of creating these vibrant combs using plastic injection molding machines. We will delve into the technology behind these machines, their benefits, and the leading manufacturers in the industry.

Section 1: Understanding Plastic Injection Molding Machines

Plastic injection molding machines are instrumental in producing a wide range of plastic products, including hair combs. These machines use a combination of heat, pressure, and molds to inject molten plastic into a specific shape. The process begins with the melting of plastic pellets, which are then injected into the mold cavity. Once the plastic solidifies, the mold opens, and the finished product is extracted.

Section 2: The Power of 2 Colour Comb Molding

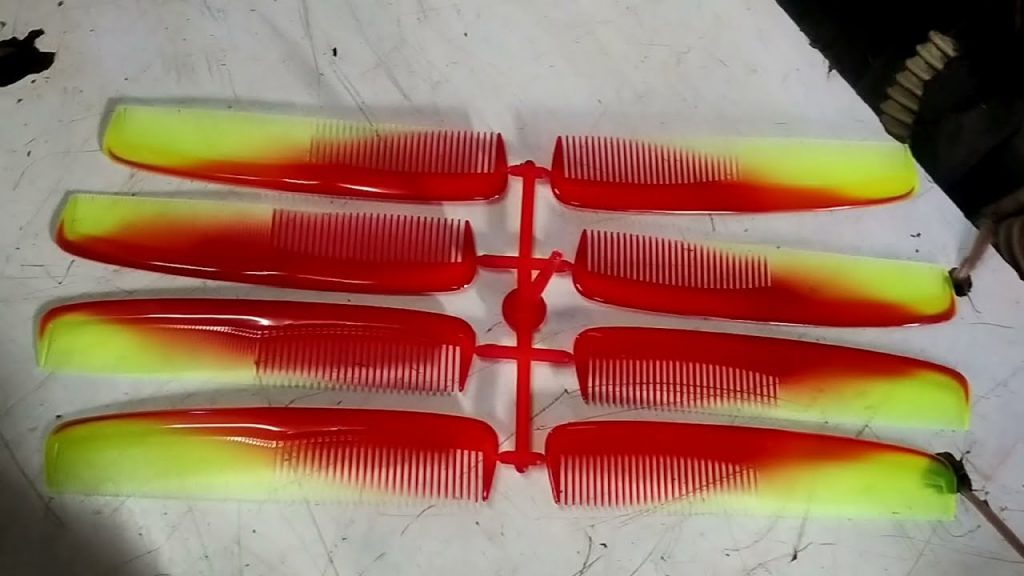

The 2 Colour Comb, also known as "2 screw barrel unit" or "2 colour ki kangi," is a popular choice among individuals who seek to add a touch of vibrancy to their hairstyles. This type of comb is created by using a plastic injection molding machine equipped with a 2 screw barrel unit. The two screws facilitate the injection of two different colors of molten plastic, resulting in a comb with contrasting shades.

Section 3: Benefits of 2 Colour Comb Plastic Injection Molding Machines

- Versatility: With the ability to inject two different colors simultaneously, these machines offer immense creative possibilities. Manufacturers can produce combs with intricate designs, patterns, and color combinations, catering to the diverse preferences of consumers.

- Efficiency: By utilizing a single machine to create 2 Colour Combs, manufacturers can streamline their production process, reducing costs and maximizing productivity.

- Durability: Plastic injection molding ensures that the combs are sturdy, long-lasting, and resistant to breakage. This durability ensures that customers can enjoy their combs for an extended period.

Section 4: Leading Plastic Injection Machine Manufacturers

When it comes to investing in plastic injection molding machines, it is crucial to choose a reliable and reputable manufacturer. Some of the leading manufacturers in the industry include:

- [Manufacturer 1]: Known for their innovative technology and commitment to quality, this manufacturer offers a wide range of plastic injection machines suitable for creating 2 Colour Combs.

- [Manufacturer 2]: With years of experience and a track record of delivering high-performance machines, this manufacturer is a trusted name in the industry.

- [Manufacturer 3]: Renowned for their customer-centric approach, this manufacturer provides comprehensive support and after-sales services, ensuring a seamless experience for their clients.

Section 5: Conclusion

The creation of 2 Colour Combs through plastic injection molding machines has revolutionized the hair accessory industry. The versatility, efficiency, and durability offered by these machines make them an ideal choice for manufacturers seeking to produce vibrant and high-quality combs. By partnering with leading plastic injection machine manufacturers, businesses can unlock the full potential of this technology, ensuring success in the competitive market.

Check out the leading manufacturers for professional coil packing solutions here:" Plastic Injection Machine

"Mastering the Art of 2 Colour Comb Plastic Injection Molding: Discover Top Plastic Injection Machine Manufacturers"