Check the coil packing solution with leading manufacturers for the professional solution here:

Title: Enhancing Efficiency with Industrial Robot Technology in Pick and Place Tasks

Introduction:

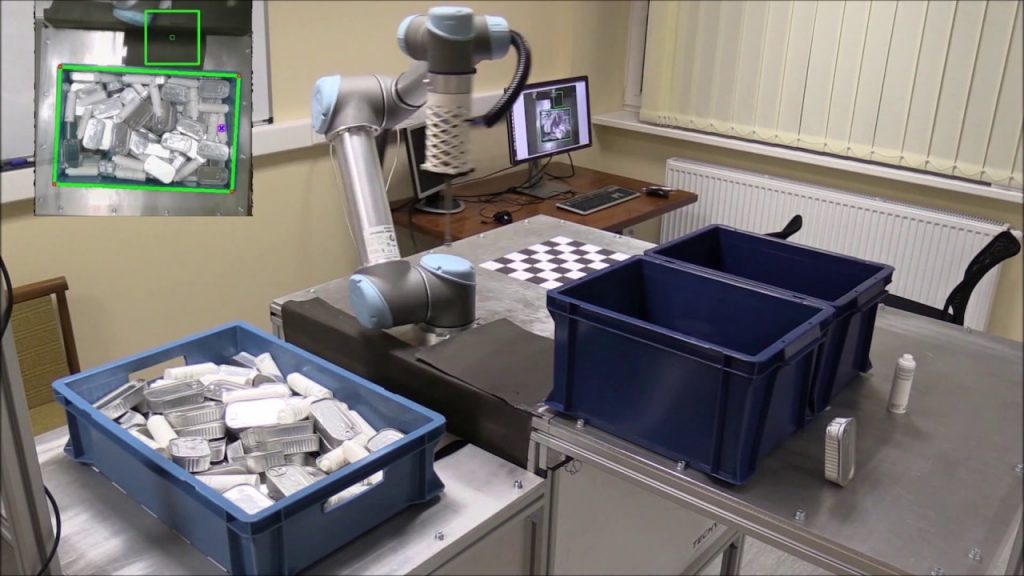

Industrial Robot Technology has revolutionized the manufacturing industry by automating various tasks, including pick and place operations. In this YouTube video, we will demonstrate the implementation of a pick and place task using Industrial Robot Technology. The video showcases the seamless handling of two kinds of objects, namely tubes and cans, which are randomly placed on a conveyor belt. By leveraging the power of Computer Vision, Artificial Intelligence, and Industrial Robot systems, this demonstration highlights the potential of smart production in optimizing efficiency.

Section 1: Industrial Robot Technology for Pick and Place Tasks

In today's fast-paced manufacturing environment, the ability to efficiently handle objects is crucial. Industrial Robot Technology offers a solution by automating pick and place tasks with precision and speed. By programming robots to identify, grasp, and relocate objects, manufacturers can achieve higher productivity and accuracy while reducing labor costs.

Section 2: The Power of Computer Vision and Artificial Intelligence

To enable robots to effectively perform pick and place tasks, Computer Vision plays a vital role. By integrating cameras and sensors, the system can capture visual information and process it using Artificial Intelligence algorithms. This allows the robot to recognize and differentiate between different objects, enabling it to make informed decisions during the pick and place process.

Section 3: Implementation of Pick and Place Task

In this demonstration, we witness the seamless implementation of a pick and place task using Industrial Robot Technology. The randomly placed tubes and cans on the conveyor belt are effortlessly recognized by the robot's vision system. With the help of Artificial Intelligence algorithms, the robot accurately identifies the type of object and determines the optimal grip and placement strategy.

Section 4: Benefits of Industrial Robot Technology in Smart Production

The integration of Industrial Robot Technology in smart production brings numerous benefits to manufacturers. Firstly, it enhances efficiency by eliminating human errors and reducing cycle times. Secondly, it improves product quality through consistent handling and placement. Lastly, it allows manufacturers to reallocate human resources to more complex tasks, further optimizing the production process.

Section 5: The Future of Industrial Robot Technology

As technology continues to advance, the potential of Industrial Robot Technology in the manufacturing industry is boundless. With ongoing research and development, we can expect further improvements in accuracy, speed, and adaptability. Industrial Robot systems will continue to evolve, enabling manufacturers to achieve even higher levels of productivity and efficiency.

Conclusion:

The demonstration of pick and place task implementation using Industrial Robot Technology showcased the power of automation in the manufacturing industry. By leveraging Computer Vision, Artificial Intelligence, and Industrial Robot systems, manufacturers can optimize efficiency, improve product quality, and pave the way for smart production. Embracing Industrial Robot Technology is a step towards a more productive and competitive future in manufacturing.

Check the coil packing solution with leading manufacturers for the professional solution here: [insert relevant link]. Industrial Robot

"Revolutionizing Smart Production: Exploring Computer Vision, AI, and Industrial Robot Systems for Advanced Industrial Robotics"