Steel Coil Strapping Machines Designed for Multi-Width Coil Processing?

As a factory manager, you know the pressure. A new order comes in, and the specs are different. The coil width changes. Suddenly, your entire packaging line grinds to a halt. Workers scramble to adjust guides, change settings, or worse, you realize your machine simply can't handle it. This downtime isn't just frustrating; it's money burning. Your production line, optimized for speed, gets choked at the final stage by inflexible equipment. I've been there, on both sides of this problem—first as an engineer dealing with these bottlenecks and later building machines to solve them. The quest for a packaging solution that keeps pace with diverse production is real and urgent. (steel coil packaging line bottleneck, multi-width coil processing challenges)

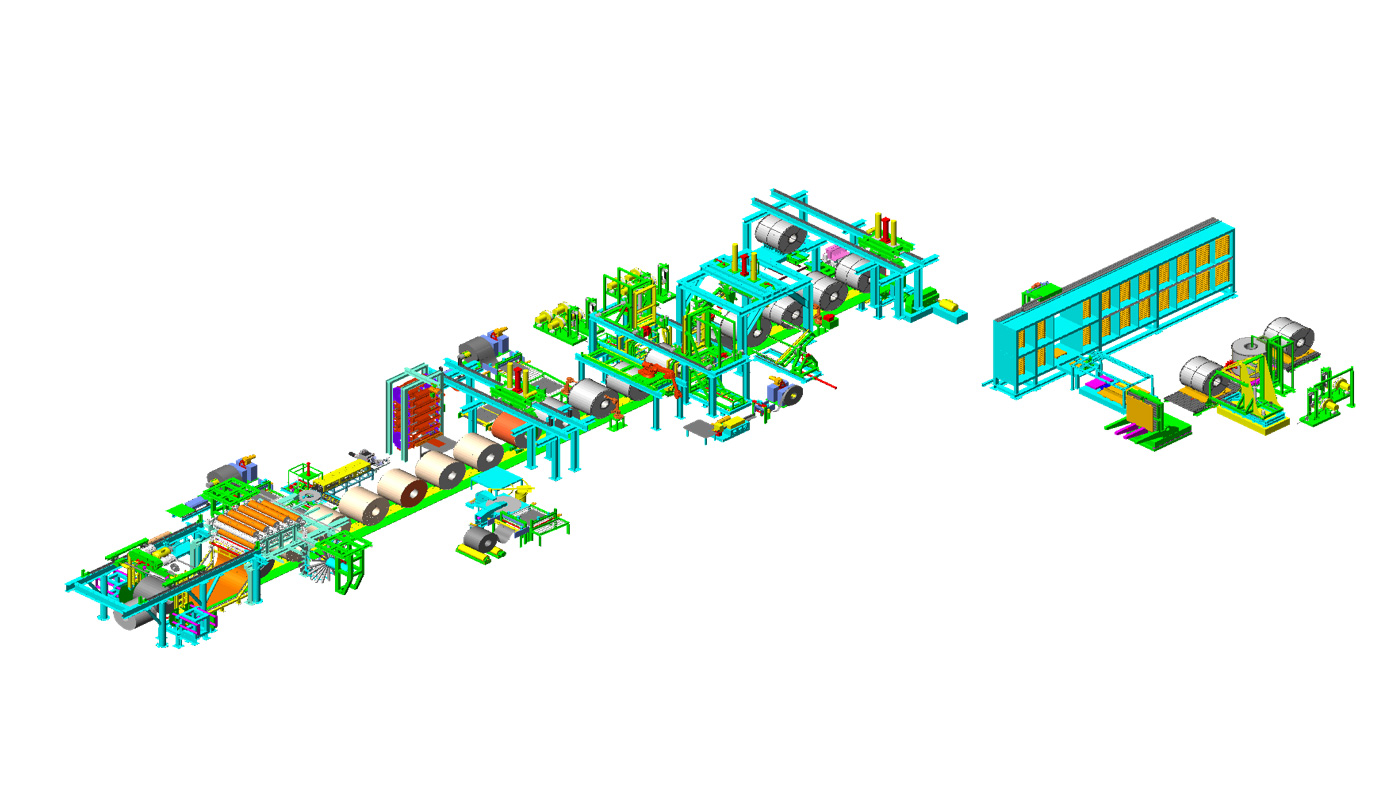

A steel coil strapping machine designed for multi-width coil processing is an automated system that can quickly and automatically adjust to secure coils of varying widths without manual intervention or lengthy changeover times. It uses programmable logic controllers (PLCs), adjustable guiding systems, and often robotic arms to apply straps precisely, ensuring consistent packaging quality across different product sizes and maximizing line uptime. (automated adjustable coil strapping system)

This flexibility is no longer a luxury; it's a necessity for modern metal service centers and mills. But what does "designed for multi-width" truly mean? Is it just a marketing term, or are there specific engineering principles that make it work? More importantly, how do you choose the right one for your specific mix of products—from narrow strips to wide plates? Let's move beyond the sales brochure and dive into the core features that separate a truly adaptable machine from a rigid one. We'll break down the key questions you should be asking.

1. What Core Features Define a True Multi-Width Strapping Machine?

Imagine a machine that needs a 30-minute setup for every new coil width. That's not a solution; it's a new problem. A genuine multi-width machine is defined by its quick-change capabilities and intelligent control. The first sign is a lack of manual cranks and bolts for adjustment. Instead, look for servo-driven components. The side guides that position the coil should move automatically based on the input from a sensor or the production order data. The strapping head's travel path must also adjust automatically to center the strap on coils of any width within its range. This core feature set turns width variation from a stoppage into a seamless, programmed step. (servo-driven coil guide adjustment, automatic strap head positioning)

The core features that define a true multi-width strapping machine are automatic width adjustment via servo motors, integration with plant data systems (like MES or ERP), a programmable logic controller (PLC) with recipe management, and adaptive tensioning systems that account for coil dimensions. These features work together to eliminate manual changeover and ensure consistent strap placement and tension regardless of coil size. (PLC recipe management for coil strapping)

🛠️ Deconstructing the "Adaptive" Package

A machine's adaptability isn't one feature; it's a system. Let's look at the components:

| Component | Fixed Machine Problem | Multi-Width Machine Solution | Key Benefit |

|---|---|---|---|

| Guiding System | Manual rails, physical stops. | Servo-motor driven side guides. | Touchscreen width input, change in <10 seconds. |

| Strapping Head | Fixed travel path. | Head moves on a servo-driven beam. | Strap is always centered, even on odd widths. |

| Control System | Basic push-button operation. | PLC with recipe storage (e.g., "Coil Type A: 1200mm"). | Recalls settings instantly, eliminates operator error. |

| Tension Control | Single setting. | Adaptive tensioning based on width/diameter input. | Prevents damage to narrow/soft coils, ensures security on wide ones. |

🔍 The Critical Link: System Integration

The most advanced machine is still an island if it doesn't talk to your mill. True multi-width processing requires upstream communication. The best practice is for the strapping machine to receive data directly from the coil production database or the preceding process (like the slitter or cut-to-length line). When coil ID "X237" arrives, the machine already knows its width, diameter, and required strap pattern. This is the difference between automation and intelligence. Without it, an operator still has to key in data, which is a point of potential delay and mistake. When evaluating suppliers like Fengding or Wuxi Buhui, ask specifically about their standard communication protocols (e.g., Profibus, Ethernet/IP) and their experience with direct MES integration. This is where a partner with deep industry knowledge proves invaluable. (MES integration for packaging lines, upstream data communication protocols)

2. How Does Multi-Width Capability Directly Solve Factory Pain Points?

Managers like Michael don't buy features; they buy solutions to headaches. A multi-width strapping machine isn't about cool robotics; it's about attacking your top-line problems: downtime, safety risks, and waste. Let's connect the dots. Every time your line stops for a width changeover, you lose production minutes. Multiply that by multiple changeovers per day, and the lost capacity is staggering. Furthermore, manual adjustments often require workers to be near moving parts or heavy coils, increasing the risk of pinch-point injuries. A machine that adjusts automatically keeps personnel at a safe distance. Finally, inconsistent manual strapping on different widths leads to loose bands (causing coil collapse in transit) or overly tight bands (damaging the product edge). An automated system applies the exact same optimized force every time. (reducing packaging line downtime, eliminating manual adjustment safety risks)

Multi-width capability directly solves critical factory pain points by eliminating production line stoppages for changeovers, removing workers from hazardous adjustment tasks near the coil, and ensuring consistent, damage-free strap application across all product sizes. This translates to higher throughput, a safer workplace, and reduced product loss during shipping. (consistent strap application for product protection)

💡 From Pain Point to ROI: A Practical Scenario

Consider a plant that processes 5 different coil widths daily, with an average of 3 changeovers. Each manual changeover takes 15 minutes of line stoppage and 2 workers.

- The Old Way (Manual): 3 changes/day 15 minutes = 45 minutes of lost production daily. 2 workers 15 minutes * 3 = 90 minutes of diverted labor daily. Add potential for product damage from inconsistent strapping.

- The New Way (Automatic Multi-Width): Changeover time: ~30 seconds (automatic recall). Lost production: ~1.5 minutes. Labor: Zero direct involvement. Product damage: Drastically reduced.

The Return on Investment (ROI) calculation becomes clear. You're buying back nearly an hour of production time every day and reallocating skilled labor to more valuable tasks. For a manager under pressure to boost output and control costs, this is a direct path to hitting those goals. The machine pays for itself not just in labor savings, but in throughput capital. When suppliers like Fengding provide ROI calculators, they are modeling this exact scenario—converting technical features into tangible financial benefits. (ROI calculation for automated packaging, throughput capital increase)

3. What Are the Key Considerations for Integration Into an Existing Line?

Buying the machine is only half the battle. The other half is making it work seamlessly with your current setup. A poorly integrated machine becomes a very expensive bottleneck. The first consideration is physical footprint and flow. You must map the coil's path from the previous station (e.g., weighing scale, conveyor) through the strapper and to the next point (e.g., labeling, storage). Is there enough space? Does the machine's infeed/outfeed height match your conveyors? Next is power and utilities. Does it require a new 3-phase connection? What about compressed air quality and capacity? The most technical, yet crucial, aspect is control integration. Can your existing PLC talk to the new machine's PLC? Will you need a separate HMI (Human-Machine Interface) screen, or can controls be merged? (packaging line integration planning, PLC communication for new equipment)

The key considerations for integrating a multi-width strapping machine into an existing line are: 1) Physical layout and material flow compatibility, 2) Power, air, and utility requirements, 3) Control system communication and data exchange protocols, and 4) The training plan for maintenance and operational staff to ensure long-term reliability. (material flow compatibility analysis)

📐 A Step-by-Step Integration Checklist

Don't get caught off guard. Work with your supplier through this list:

- Site Survey & 3D Modeling: A reputable supplier should insist on a site visit. They should provide a 3D model of the machine in your proposed location, checking for clearances and access for maintenance.

- Interface Point Specification:

- Mechanical: Conveyor type, speed, height, and stopping mechanism (photocell, physical stop).

- Electrical: Signal exchange list (e.g., "Coil in Position", "Machine Cycle Complete", "Fault Alarm").

- Data: Agreed-upon data string format for coil dimensions (e.g.,

WIDTH:1500, DIAM:800).

- Phased Commissioning Plan: The startup should not be "flip the switch on Monday." Plan for:

- Week 1: Mechanical and electrical installation, no product.

- Week 2: Dry-cycle testing and control signal verification.

- Week 3: Run-with-product testing at slow speed, then ramp up.

- Spare Parts & Local Support: Ensure critical spare parts (like seals, sensors, fuses) are on-site at commissioning. Discuss the supplier's local technical support response time. A partner who understands your operational pressure will have a clear support protocol.

This level of detailed planning separates a transactional vendor from a true partner. It's the difference between a smooth upgrade and a months-long disruption.

4. How to Evaluate and Choose the Right Supplier for Your Needs?

The market has options, from premium brands to cost-effective solutions. Your choice must balance performance, durability, and support. Price is a factor, but the lowest upfront cost often leads to the highest lifetime cost through downtime and poor service. Start by evaluating technical capability and specialization. Does the supplier have a proven track record with multi-width applications in your industry (steel, aluminum, copper)? Ask for case studies or customer references you can contact. Next, scrutinize build quality and key components. Are the servo motors from a reputable brand (e.g., Siemens, Yaskawa)? Is the frame construction robust enough for your 24/7 environment? Finally, and most critically, assess after-sales service and technical support. What is their guaranteed response time? Do they have trained engineers in your region, or will support require a long international flight? (evaluating packaging machine suppliers, after-sales service for industrial equipment)

To choose the right supplier, prioritize those with demonstrable experience in multi-width coil applications, inspect the quality of core components (like servos and PLCs), and rigorously evaluate their local service and support structure. The ideal partner offers not just a machine, but a long-term solution backed by accessible expertise. (industrial equipment supplier evaluation criteria)

🏆 Supplier Comparison: Beyond the Brochure

Here is a simplified framework to compare potential partners:

| Evaluation Criteria | Basic Supplier | True Partner (e.g., Fengding) |

|---|---|---|

| Technical Proposal | Generic machine specs. | Customized layout drawing & integration plan for your line. |

| Core Components | Generic or lowest-cost brands. | Uses top-tier, industry-standard brands for critical parts. |

| Control Integration | "Our machine works standalone." | Proactively discusses communication protocol and provides interface documents. |

| Service Response | "Call our headquarters." | Has a defined local/regional support network with spare parts inventory. |

| Industry Knowledge | Sells machines. | Understands your production bottlenecks, safety regulations, and end-customer requirements. |

Your goal is to find a supplier who acts as an extension of your engineering team. They should ask detailed questions about your product mix, shift patterns, and future plans. For a complex investment like a multi-width strapper, the relationship with the supplier is as important as the technology itself. A partner like Fengding typically stands out because their engineers often come from a production background—they've faced the same problems you're trying to solve.

Conclusion

Investing in a multi-width steel coil strapping machine is a strategic decision to eliminate a major production bottleneck, enhance safety, and protect product quality. By focusing on automatic adjustment, seamless integration, and a reliable supplier partnership, you secure a solution that grows with your business. For a durable and intelligent choice, explore the engineered solutions from Steel Coil Strapping Machines manufacturers who build for the real world.