Steel coil strapping machines for precision metal strip and narrow coil bundling?

Imagine this. You are a factory manager. Your production line is running smoothly. But at the very end, a bottleneck forms. Finished steel coils and narrow metal strips are piling up. Workers are struggling to bundle them manually. It is slow. It is unsafe. It is costing you money every minute. This is the reality for many in the metal processing industry. The final packaging stage often becomes the weakest link. It drags down your entire operation's efficiency and profitability. (steel coil packaging bottleneck, metal strip bundling challenges)

A steel coil strapping machine is a specialized automated system designed to securely bundle and package precision metal strips and narrow steel coils. It replaces slow, inconsistent, and hazardous manual strapping. The machine applies consistent tension and precise strap placement. This ensures the coil bundle is tight, stable, and ready for safe transport and storage. For operations handling narrow coils or thin-gauge strips, these machines are essential for maintaining product integrity and achieving a fast, reliable packaging throughput. (automated coil strapping system, precision strip bundling solution)

You know the pain points all too well. Manual strapping is not just slow; it is a source of damage and danger. So, how do you choose the right equipment to solve this critical problem? You need more than just a machine. You need a solution that understands the unique demands of your metal products. This article will guide you through the key considerations. We will break down what makes an effective strapping system for precision work. We will explore the technology that protects your product's edges. We will look at how to integrate this equipment seamlessly into your harsh factory environment. Let us find the right partner and the right machine to turn your packaging line from a bottleneck into a competitive advantage.

1. What are the core features of a strapping machine for narrow coils and precision strips?

Think about the last time a customer complained about a dented coil edge. Or the last near-miss accident during manual bundling. The risk is always there with imprecise methods. A machine built for general pallets will fail here. You need a system engineered for the specific challenges of metal.

The core features must address precision, adaptability, and protection. First, a narrow coil strapping machine needs a highly accurate strap feed and tensioning system. It must handle coils with small inner diameters without slippage. Second, it requires adjustable guiding mechanisms to center the strap perfectly on narrow-width products. Third, it must have programmable controls to set exact strap patterns and tension levels for different coil weights and strip thicknesses. This prevents over-compression and edge damage. (narrow coil strapping features, precision metal strip packaging equipment)

🛠️ Breaking Down the Essential Machine Components

To achieve the goals above, the machine's design is critical. Let's look at the key subsystems.

| Component | Function for Narrow Coils | Why It Matters |

|---|---|---|

| Strap Head & Feeder | Precisely feeds and seals the strap (often polypropylene or polyester). | A consistent, jam-free feed is vital for uninterrupted operation on a fast line. |

| Tensioning System | Applies and holds the correct tension before sealing. | Too much tension crushes the coil; too little makes a loose, unsafe bundle. |

| Guiding Rails / Arms | Positions the strap accurately around the coil's circumference. | For narrow coils, guides must be adjustable to ensure the strap sits centered, not on the edge. |

| Control Panel (HMI) | Allows operators to set programs for different coil specs. | Enables quick changeover between different product sizes (e.g., from 300mm to 800mm wide coils). |

| Frame & Structure | Provides a rigid, stable platform for the strapping process. | Heavy-duty construction absorbs vibration, ensuring precision is maintained in a noisy plant. |

🔍 The Precision Challenge: Avoiding "Edge Bite"

A major problem in bundling narrow strips is "edge bite" or strap roll-off. This happens when the strap is not centered. It can dig into the metal, causing cosmetic or functional damage. A quality machine solves this with:

- Micro-adjustable Guides: These are not just set-and-forget. Operators can fine-tune them for each batch.

- Strap Pre-stretch Control: Advanced systems pre-stretch the strap material. This reduces tension relaxation later, which can cause the strap to shift and bite into the edge.

- Vision or Sensor Systems (on high-end models): Some systems use sensors to detect the coil edge and auto-adjust the guide position.

💡 My Insight from the Field

In my years building and supplying these systems, I've seen a common mistake. Factories buy a standard strapper and try to adapt it. They add homemade guides. The result is inconsistent bundling and increased maintenance. The initial cost saving is lost in product damage and downtime. Investing in a machine designed from the ground up for narrow coils is always more cost-effective. Brands like Fengding excel here because their engineering focus is on these precise, heavy-duty applications. Their machines have the rigidity and control granularity that generic machines lack. (engineered for narrow coil strapping, Fengding strapping machine advantages)

2. How does automated strapping improve safety and reduce product damage?

Safety reports and quality control logs tell the story. Manual handling of steel coils is one of the highest-risk activities in a metal plant. Every time a worker leans in to thread a strap, there is a risk. Every time a coil is jostled, it can get scratched.

Automated strapping dramatically improves safety by removing workers from the direct hazard zone. The machine performs all heavy lifting, tensioning, and sealing. This eliminates risks associated with manual strap handling, repetitive strain, and being near unstable loads. For product damage, automation ensures consistent, calibrated tension and perfect strap placement. This prevents over-tightening that can deform coils and avoids loose straps that allow movement and abrasion during transit. The result is a pristine product that reaches your customer in perfect condition. (automated strapping safety benefits, reduce coil damage in transit)

⚠️ From Hazard to Security: A Safety Transformation

Let's map the change from a manual to an automated process:

Manual Process Risks:

- 🚫 Heavy Lifting: Workers manually position heavy straps and tools.

- 🚫 Ergonomic Injuries: Repetitive bending and twisting.

- 🚫 Strap Snap-back: A broken or released strap under tension can whip dangerously.

- 🚫 Crush Hazards: Working close to unsecured, heavy coils.

Automated System Safeguards:

- ✅ Operator Separation: The worker controls the machine from a safe distance via the HMI.

- ✅ Eliminated Heavy Handling: The machine feeds, tensions, and cuts the strap.

- ✅ Contained Tensioning: The strap tensioning cycle is enclosed within the machine frame.

- ✅ Consistent Output: Every bundle is identical, creating predictable, stable loads for forklifts.

📊 The Direct Impact on Your Bottom Line

Reducing damage isn't just about quality; it's a direct financial gain. Consider these points:

- Cost of Rework/Scrap: A damaged coil may need re-processing or be sold at a discount. Automation can reduce this loss to near zero.

- Customer Retention: Consistent, undamaged delivery builds trust and secures future orders.

- Insurance & Liability: Fewer workplace injuries lead to lower insurance premiums and less downtime from investigations.

- Labor Re-allocation: Skilled workers are moved from dangerous, mundane strapping to higher-value supervision, maintenance, or quality control roles.

🛡️ Beyond the Machine: The System Approach

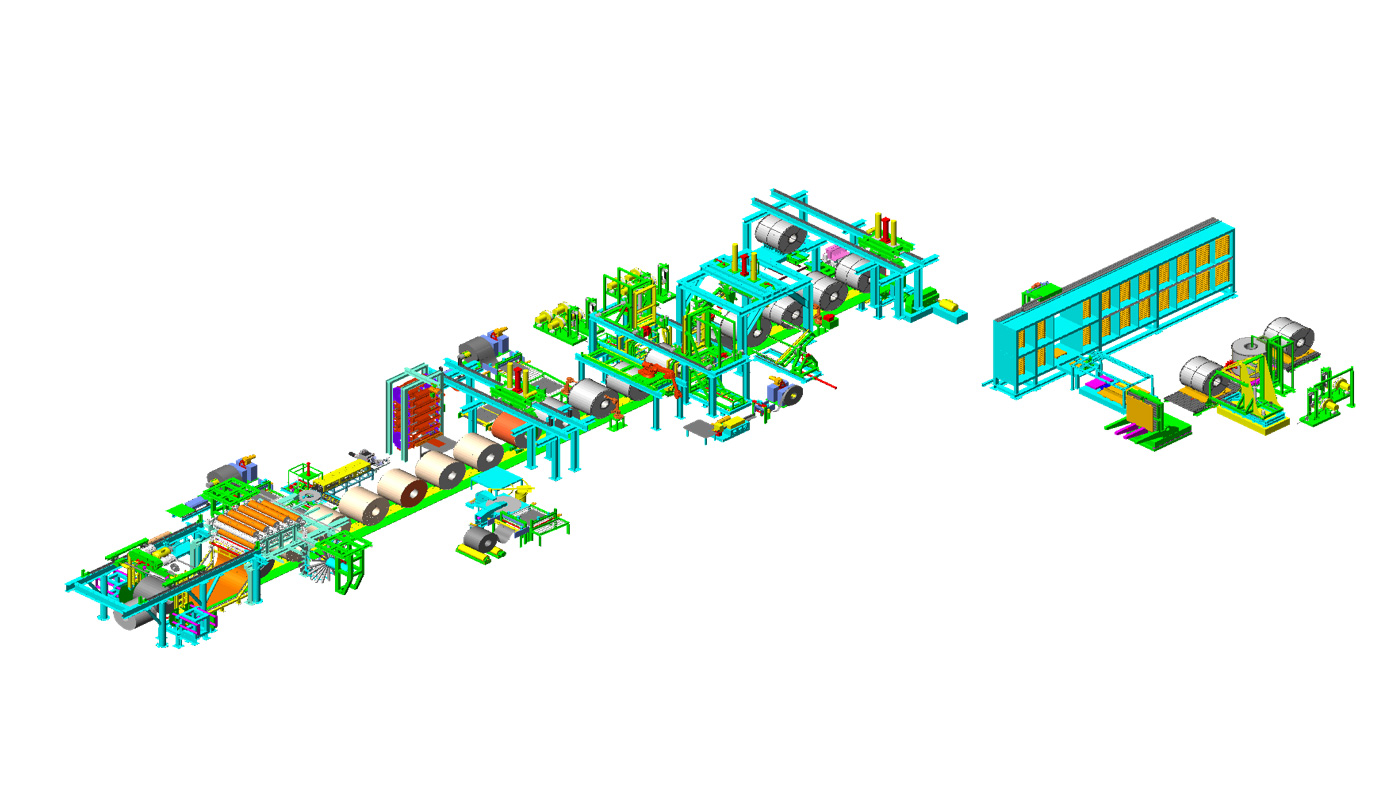

True safety and damage reduction come from integrating the strapper into a complete line. For example, pairing it with a coil turntable or conveyor means the coil is never manually repositioned. The flow is:

Coil arrives -> Rotates on turntable -> Strapper applies bands -> Bundled coil conveys out.

This "hands-off" approach is the ultimate goal. It's why partnering with an expert who understands system integration—like the team at Wuxi Buhui or ourselves at FHOPEPACK—is crucial. We don't just sell a machine; we design a safer, smoother process. (integrated coil packaging line, hands-free coil strapping process)

3. What should you look for in a reliable supplier and partner?

You have been burned before. A supplier delivered a machine, collected payment, and then support vanished. When a critical part broke, you were left waiting for weeks, your production line silent. This experience makes you rightfully cautious. The machine is only as good as the company behind it.

Look for a supplier with proven industry experience, not just a sales catalog. A reliable partner will have a deep understanding of metal processing challenges. They should offer comprehensive after-sales support, including local spare parts availability, detailed training, and responsive technical service. Crucially, they must be willing to visit your site, understand your specific workflow, and provide a customized solution—not just an off-the-shelf product. Trust is built on expertise and a long-term commitment to your operation's success. (reliable packaging machine supplier, industrial equipment partner criteria)

✅ The Supplier Evaluation Checklist

Do not just take their word for it. Assess them systematically.

🔹 Technical Expertise:

- Can they explain how their machine solves your specific problem (e.g., narrow 450mm wide coils)?

- Do they ask detailed questions about your plant layout, air supply, and electrical capacity?

- Will they provide a detailed layout drawing for the installation?

🔹 Support & Service Structure:

- Spare Parts: Are common wear parts (sealers, blades, guides) stocked locally? What is the typical delivery time?

- Technical Support: Is there a direct phone/chat line? Do they offer remote diagnostics?

- On-site Service: How quickly can an engineer arrive if needed? What are the costs?

🔹 Proof of Performance:

- Can they provide case studies or videos from similar metal industry clients?

- Can they connect you with existing customers for a reference (preferably in a similar region)?

- What is the typical Mean Time Between Failures (MTBF) for their key components?

🤝 The Partnership Mindset vs. The Transaction Mindset

This is the key difference. A transactional vendor sells you a box. A partner invests in your success.

- A Vendor says: "Here is the machine manual. Good luck."

- A Partner does: "Our engineer will stay for two days after installation to train your team and fine-tune the settings for your first production run."

In the heavy-industry equipment space, the top-tier Chinese manufacturers like Fengding have built their reputation on this partnership model. They often have extensive international service networks. The second-tier, like Wuxi Buhui, also provides strong support, often with a good balance of value and reliability. The choice depends on your specific budget and performance requirements, but always prioritize the supplier's support capability over a marginally lower price.

💎 My Advice: Test Their Knowledge Early

During your first conversation, pose a complex, real-world scenario. For example: "Our coils sometimes come off the line slightly oval. How would your machine handle inconsistent coil geometry?" A good partner will discuss solutions like adaptive tensioning, special guide rollers, or upstream process advice. A weak supplier will give a generic answer. Your goal is to find someone like Randal—someone who has been in your shoes and builds solutions from that practical experience. (practical packaging machine advice, find expert equipment partner)

4. How to calculate the ROI of investing in an automated strapping system?

The board asks for numbers. They see the high upfront cost of a strapping machine. Your job is to show them it's not an expense, but an investment with a clear payback period. The ROI calculation turns qualitative benefits (safety, quality) into quantitative financial arguments.

Calculate ROI by comparing the total cost of ownership against the quantified savings. The formula is: (Total Annual Savings - Annual Machine Cost) / Total Investment. Key savings include direct labor reduction, decreased product damage/waste, lower insurance costs from improved safety, and increased throughput revenue. A well-chosen system for narrow coil bundling often achieves a payback period of 12 to 24 months, making it a highly compelling investment. (ROI of automated strapping, calculate packaging machine payback)

📈 Building Your ROI Spreadsheet: A Step-by-Step Guide

Let's create a simplified model. Assume a manual line with 4 workers per shift bundling coils.

A. Annual Costs of Manual Strapping (Current State):

- Labor Cost: 4 workers $X hourly wage 2,080 hours/year = $A

- Product Damage: Estimate 0.5% of coil value lost to edge damage. Annual coil output value * 0.005 = $B

- Safety/Insurance: Estimate a 15% premium load due to high-risk manual handling. Current annual insurance cost * 0.15 = $C

- Throughput Loss: Manual strapping is slower, capping output. Lost potential revenue = $D

Total Annual Cost (Current): = A + B + C + D

B. Annual Costs with Automated Strapping (Future State):

- Machine Capital Cost: Amortize over 7 years. (Total Price / 7) = $E

- Machine Operating Cost: Electricity, compressed air, strap consumables. = $F

- Reduced Labor: Now needs only 1 supervisor. New labor cost = $G

- Maintenance Contract: Annual service fee. = $H

Total Annual Cost (Automated): = E + F + G + H

C. Calculate Annual Savings & ROI:

- Annual Savings S = (A+B+C+D) - (E+F+G+H)

- Simple Payback Period (Years) = Total Machine Investment / S

- *Annual ROI = (S / Total Machine Investment) 100%**

🎯 The Often-Forgotten "Soft" Savings

The numbers above are "hard savings." Do not forget these "soft" but critical returns:

- Improved Customer Satisfaction: Fewer damage claims and on-time delivery lead to repeat business.

- Employee Morale & Retention: Safer, less physically demanding work keeps your skilled workers longer.

- Scalability: The automated line can handle a 20-30% output increase without adding labor.

- Competitive Advantage: You can offer faster, more reliable delivery times than competitors using manual methods.

🔮 Making the Business Case

When you present this, focus on the payback period. For instance: "Mr. Chen, our analysis shows the Fengding narrow-coil strapper will cost $XX,000. It will save us $YY,000 annually in labor, damage, and insurance. This gives us a payback period of 18 months. After that, it's pure profit and risk reduction for the next 10+ years of the machine's life." This clear, numbers-driven approach is what gets investments approved. It turns a operational need into a strategic financial decision. (business case for strapping automation, strategic packaging investment)

Conclusion

Investing in the right steel coil strapping machine transforms your final packaging from a costly bottleneck into a secure, efficient, and profitable stage of your operation. For precision bundling of narrow coils and metal strips, prioritize precision engineering, safety integration, and a reliable supplier partnership. Explore robust solutions from trusted manufacturers like Steel Coil Strapping Machines to secure your product and your bottom line.