In today's fast-paced manufacturing industry, efficient coil packing solutions play a crucial role in ensuring the safe and secure transportation of goods. For businesses dealing with coil products, such as steel coils, aluminum coils, or copper coils, finding the right packing solution is essential to protect the coils from damage during storage and transportation. In this YouTube video article, we will explore the benefits and features of coil packing solutions and provide valuable insights into the slit coil packaging solutions.

Coil packing solutions are specifically designed to meet the unique requirements of the coil industry. These solutions offer a comprehensive range of protective measures to ensure the coils remain intact and undamaged throughout their journey. Whether it's preventing surface scratches, protecting against moisture, or ensuring stability, coil packing solutions have got you covered.

One of the key aspects of coil packing solutions is the use of high-quality materials. These solutions often employ advanced techniques and materials such as stretch film, VCI (Volatile Corrosion Inhibitor) films, and laminated films. These materials provide excellent protection against external elements and help maintain the coil's integrity.

Additionally, coil packing solutions are highly customizable. Manufacturers understand that every coil product is different and requires tailored packaging solutions. From adjustable packing tension to variable wrapping patterns, these solutions can be customized to fit the specific needs of your coils. This level of flexibility ensures optimum protection and minimizes the risk of damage.

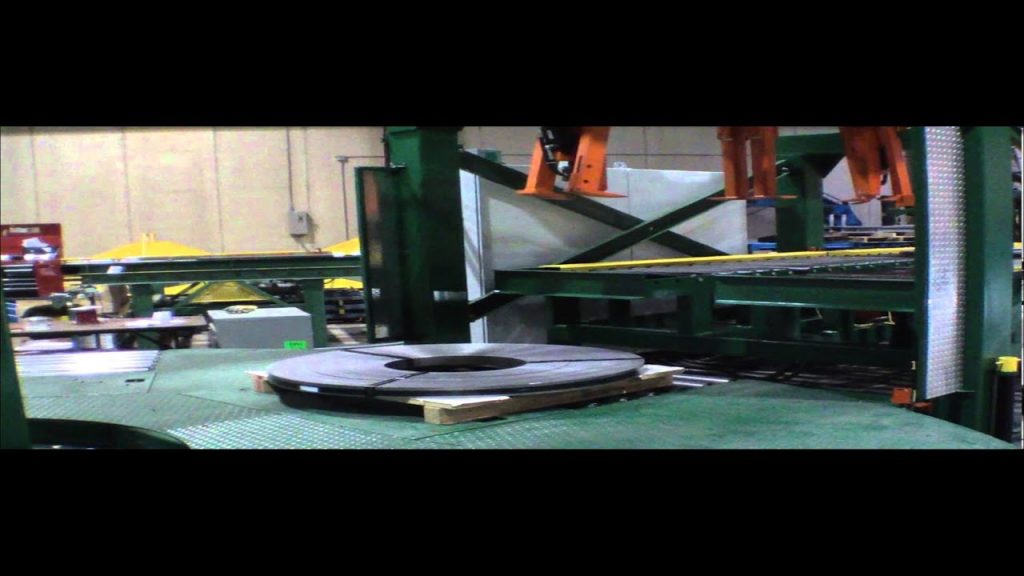

Now, let's delve into the world of slit coil packaging solutions. Slit coils, which are coils that have been cut into narrower widths, require specialized packaging techniques. Slit coil packaging solutions are designed to accommodate the unique dimensions and characteristics of slit coils.

These solutions often incorporate features such as edge protection, corner protection, and foam inserts to prevent any potential damage to the slit coils. Furthermore, slit coil packaging solutions also focus on efficient handling and storage. They offer options like interlocking systems, which allow for easy stacking and transportation of slit coils.

In-depth analysis of the coil packing solutions market reveals a growing demand for advanced automation and integration capabilities. Manufacturers are investing in cutting-edge technology to streamline the coil packaging process. This includes automated coil packing machines that can handle large volumes of coils with minimal human intervention. Such machines not only improve efficiency but also enhance safety and reduce labor costs.

Looking ahead, the future of coil packing solutions is promising. Advancements in technology and material science will continue to revolutionize the industry. We can expect more innovative solutions that provide superior protection, increased efficiency, and reduced environmental impact.

In conclusion, coil packing solutions are essential for businesses dealing with coil products. They offer a range of benefits, including customized protection, advanced materials, and efficient handling. Slit coil packaging solutions cater specifically to the unique requirements of slit coils. As the industry evolves, we can anticipate further advancements and improvements in coil packing solutions.

Check the coil packing solution with leading manufacturers for professional solutions. They have the expertise and experience to provide you with the best coil packing solution for your specific needs. Remember, investing in quality coil packing solutions is an investment in the safety and integrity of your coils. Coil packing Line

"Efficient and Secure Packaging Solutions for Slit Coils and Coil Packing: Ensuring Protection and Convenience"