If you are a programming enthusiast, you might have come across the claim that you can learn programming in just 5 minutes. But is it really possible? In reality, programming is a complex skill that requires time and effort to master. However, when it comes to industrial robots and cobots, there is a fundamental difference in terms of safety. This article will delve into the world of industrial robot programming and shed light on why cobots are also hard to program.

Industrial robots have been widely used in various industries for decades. These robots are designed to perform repetitive tasks with precision and efficiency. However, programming these robots can be quite challenging. Industrial robot programming involves writing code that controls the robot's movements and actions. This code needs to be carefully crafted to ensure that the robot performs its tasks accurately and safely.

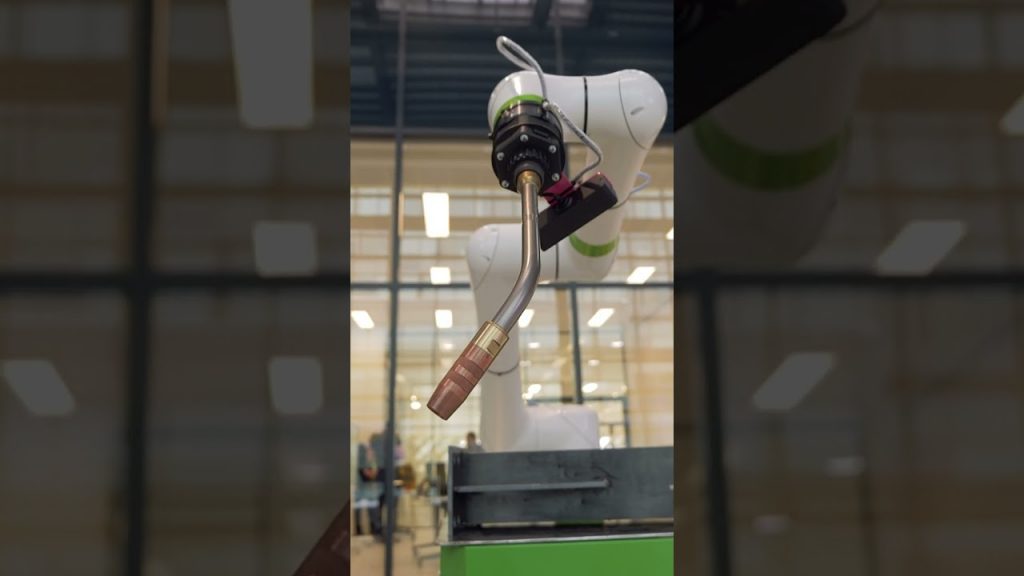

On the other hand, cobots, or collaborative robots, are designed to work alongside humans. Unlike traditional industrial robots, cobots are equipped with advanced sensors and safety features that allow them to interact with humans in a safe manner. This means that cobots can be programmed to perform tasks that require close collaboration with humans, such as assembly line tasks or delicate operations.

However, despite their safety features, programming cobots is not a walk in the park. Cobots require a different approach to programming compared to traditional industrial robots. The programming of cobots involves not only writing code for their movements but also considering the safety aspects of their interactions with humans. This requires a deep understanding of human-robot interaction and the ability to program the cobot to respond to human inputs in a safe and efficient manner.

So, why are cobots hard to program? One reason is the complexity of human-robot interaction. Unlike traditional industrial robots, cobots need to be programmed to understand and respond to human inputs. This requires advanced algorithms and programming techniques that take into account the variability and unpredictability of human behavior.

Another challenge in programming cobots is ensuring their safety. Since cobots work alongside humans, their programming must prioritize safety. This involves implementing safety features such as force sensing, collision detection, and emergency stop mechanisms. Programming these safety features requires a thorough understanding of safety regulations and standards.

In conclusion, programming industrial robots and cobots is a complex task that requires skill and expertise. While industrial robot programming focuses on precision and efficiency, cobot programming adds the additional challenge of ensuring safety in human-robot interactions. Both types of programming require a deep understanding of robotics and programming techniques. So, the next time you come across the claim of learning programming in just 5 minutes, remember that mastering the art of programming takes time and dedication.

Check the coil packing solution with a leading manufacturer for a professional solution. Industrial Robot

"Unveiling the Challenges in Programming Cobots | A Glimpse into Robotic Welding and Industrial Robot Programming"