Check out the leading manufacturer for professional coil packing solutions here: [insert appropriate URL].

Title: The Future of Industrial Robots: Revolutionizing Electric Vehicle Automation

Introduction:

As the world moves towards a greener future, the demand for electric vehicles (EVs) has been steadily increasing. With this rise, the automotive industry is faced with the challenge of efficiently producing these vehicles on a large scale. This is where industrial robots come into play. In this article, we will explore the future of industrial robots and how they are revolutionizing EV automation.

1. The Rise of Electric Vehicles:

The transition from traditional gasoline-powered cars to electric vehicles has gained significant momentum in recent years. EVs offer a cleaner and more sustainable transportation solution, reducing carbon emissions and reliance on fossil fuels. As the demand for EVs continues to grow, manufacturers face the task of increasing production while maintaining high quality and efficiency.

2. The Role of Industrial Robots:

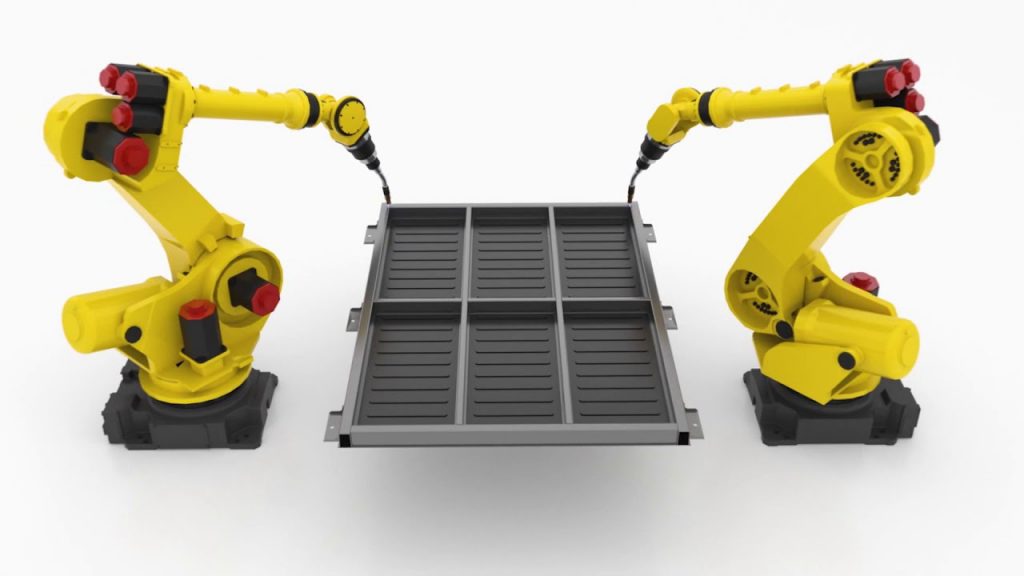

Industrial robots have emerged as a game-changer in the automotive industry. These robots play a crucial role in automating various processes, from assembly and welding to painting and packaging. With their advanced capabilities and precision, industrial robots are capable of performing tasks with speed and accuracy that surpass human capabilities. This results in faster production cycles, improved product quality, and enhanced safety in the manufacturing process.

3. Future Trends in Industrial Robotics:

a) Collaborative Robots (Cobots): Collaborative robots are designed to work alongside humans, enhancing productivity and safety. These robots can assist in tasks that are physically demanding or pose potential risks to human workers. The integration of cobots in EV manufacturing will lead to improved efficiency and reduced human error.

b) Artificial Intelligence (AI) and Machine Learning: The future of industrial robots lies in their ability to become smarter and more autonomous. AI and machine learning algorithms enable robots to analyze data, make decisions, and adapt to changing production requirements. This will result in increased productivity, as robots can continuously learn and optimize their performance.

c) Internet of Things (IoT) Integration: Connecting industrial robots to the internet allows for real-time monitoring, data analysis, and remote control. This integration enables manufacturers to have better control over their production processes, identify inefficiencies, and make informed decisions to optimize operations.

4. FANUC Automation: Leading the Way:

FANUC Automation, a pioneer in industrial robotics, has been at the forefront of driving innovation in EV automation. With their expertise in robotics and automation solutions, FANUC has developed cutting-edge technologies that cater specifically to the needs of the automotive industry. Their range of industrial robots offers unparalleled precision, reliability, and flexibility, making them ideal for EV manufacturing.

Conclusion:

The future of industrial robots in the electric vehicle industry is promising. As the demand for EVs continues to rise, the need for efficient and automated production processes becomes paramount. Industrial robots, with their advanced capabilities and continuous advancements in technology, are revolutionizing EV automation. Companies like FANUC Automation are leading the way in providing innovative solutions that enhance productivity, quality, and safety in the manufacturing of electric vehicles.

Check out the leading manufacturer for professional coil packing solutions here: [insert appropriate URL]. Industrial Robot

"The Electrifying Future: Exploring FANUC Automation and Electric Vehicles' Synergy with Industrial Robots"