Title: "Revolutionizing Packaging Efficiency with the M-421iA Packing Robot by FANUC Robotics"

Description:

Introduction:

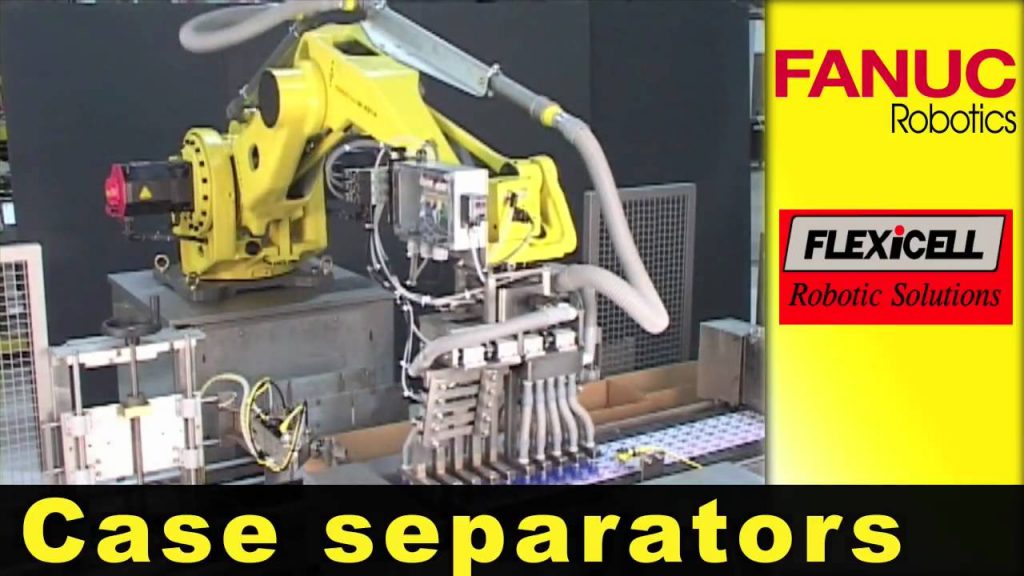

Discover the cutting-edge world of automated packing systems with the remarkable M-421iA Packing Robot by FANUC Robotics. In this captivating video, witness the seamless integration of advanced robotic technology as the M-421iA expertly packages cups directly from a filler into cases, revolutionizing the packaging process.

Video Content:

This video showcases the extraordinary capabilities of the M-421iA Packing Robot, demonstrating how it effortlessly handles the packaging of cups with utmost precision and speed. With its state-of-the-art technology, the robot seamlessly collaborates with other machinery to optimize efficiency and productivity, streamlining the entire packaging operation.

Key Highlights:

1. Unparalleled Efficiency: The M-421iA Packing Robot significantly enhances packaging efficiency by swiftly and accurately transferring cups from the filler into cases, minimizing manual labor and reducing potential errors.

2. Precision and Reliability: Equipped with advanced sensors and intelligent programming, the robot ensures precise cup placement within cases, ensuring consistent and reliable packaging results.

3. Flexibility and Adaptability: The M-421iA Packing Robot can be easily programmed to accommodate various cup sizes and packaging configurations, offering unparalleled versatility in meeting diverse packaging requirements.

4. Seamless Integration: Designed for seamless integration with existing packaging systems, the robot effortlessly collaborates with other machinery, enabling smooth operation and maximizing overall productivity.

5. Enhanced Safety: FANUC Robotics prioritizes safety, and the M-421iA Packing Robot is designed with comprehensive safety features to protect both the operators and the packaging materials.

Call to Action:

If you are amazed by the capabilities of the M-421iA Packing Robot, don't forget to hit the like button and subscribe to our channel for more fascinating videos on industrial automation. Share this video with your colleagues and friends to spread the word about the incredible advancements in automated packing systems.

Additional Tags and Keywords:

automated packing systems, M-421iA Packing Robot, FANUC Robotics, industrial automation, packaging efficiency, cup packaging, robotic technology, advanced sensors, packaging configuration, seamless integration, productivity optimization, safety features

Hashtags:

#AutomatedPackingSystems #M421iAPackingRobot #FANUCRobotics #IndustrialAutomation #PackagingEfficiency #RoboticTechnology #ProductivityOptimization #SafetyFirst

Here's a sample tilter program for the M-421iA Packing Robot by FANUC Robotics Industrial Automation:

1. Start the program by initializing the robot and setting the required parameters.

2. Move the robot to the initial position where the object to be tilted is located.

3. Use the robot's gripper to securely hold the object.

4. Move the robot to the desired tilting position using appropriate joint or Cartesian motion commands. This can be achieved by specifying the required joint angles or end-effector positions.

5. Activate the tilter mechanism of the robot by sending appropriate signals to the tilter control system. This could involve activating a motor or pneumatic system.

6. Wait for the tilter mechanism to tilt the object to the desired angle.

7. Deactivate the tilter mechanism once the desired tilt angle is reached.

8. Move the robot back to the initial position, ensuring the tilted object remains securely gripped.

9. Release the gripped object using the robot's gripper.

10. End the program.

Note: This is a basic outline of a tilter program for the M-421iA robot. The specific commands and instructions may vary depending on the exact configuration of the robot and tilter mechanism being used. It's important to refer to the robot's programming manual and the tilter system documentation for accurate and detailed instructions. Automatic Packing Line

#M421iA #Packing #Robot #FANUC #Robotics #Industrial #Automation