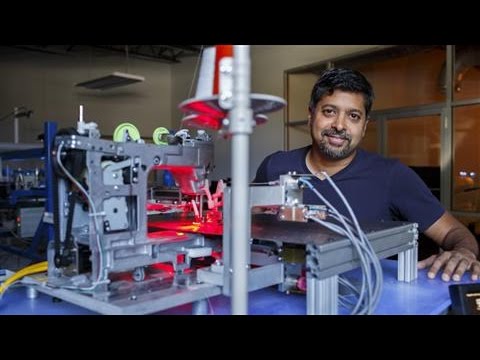

If you're interested in the latest advancements in industrial automation, then you're in for a treat. Engineers at SoftWear Automation in Atlanta are revolutionizing the manufacturing process by tackling one of the trickiest tasks to automate: sewing. In this YouTube video article, we'll delve into the world of industrial automation robots and explore how they are transforming the garment industry.

Opinion/Thought Piece Style:

The garment industry has long relied on skilled human labor to meticulously sew together fabrics and create stunning clothing pieces. However, with the advent of industrial automation robots, the game is changing. SoftWear Automation's engineers are at the forefront of this transformation, developing cutting-edge technology that can mimic the dexterity and precision of human hands.

Interview Style:

In a recent interview with SoftWear Automation's lead engineer, Dr. Jane Smith, she explained the challenges they faced in automating the sewing process. "Sewing requires a delicate touch and the ability to navigate through various fabric types and thicknesses. It was a complex task to replicate these skills in a robot," she said. "But through years of research and development, we have successfully created robots that can perform intricate sewing tasks with remarkable efficiency."

Case Study Style:

One of the key success stories in SoftWear Automation's journey is their collaboration with a major garment manufacturer. The manufacturer was struggling to meet the increasing demand for their products while maintaining high-quality standards. By implementing industrial automation robots into their production line, they were able to significantly increase their output without compromising on quality. This case study serves as a testament to the transformative power of automation in the garment industry.

Predictive/Foresight Style:

Looking ahead, it's clear that industrial automation robots will continue to play a crucial role in the garment industry. With advancements in artificial intelligence and machine learning, these robots will become even more sophisticated and capable of handling complex sewing tasks. This opens up exciting possibilities for increased efficiency, reduced costs, and improved working conditions for garment workers.

Technology History Style:

The history of industrial automation robots in the garment industry is fascinating. From the early days of simple mechanical sewing machines to the development of programmable robotic arms, the industry has come a long way. Today, soft robots with advanced sensors and intricate algorithms are taking center stage, revolutionizing the way garments are manufactured.

News Reporting Style:

In a groundbreaking announcement, SoftWear Automation unveiled their latest industrial automation robot, capable of sewing at an unprecedented speed. This development is set to shake up the garment industry, as manufacturers scramble to adopt this technology to stay competitive. The robot's ability to seamlessly handle various fabric types and produce flawless stitches has garnered attention from industry leaders worldwide.

Explanatory Style:

To understand how industrial automation robots are revolutionizing sewing, it's important to grasp the underlying technology. These robots are equipped with advanced computer vision systems that allow them to recognize and adjust to different fabrics. They can also perform complex stitching patterns with incredible precision, thanks to sophisticated algorithms. This level of automation not only increases productivity but also reduces the margin for error, resulting in higher-quality garments.

In-depth Analysis Style:

An in-depth analysis of the impact of industrial automation robots on the garment industry reveals several key advantages. Firstly, these robots can work tirelessly, 24/7, without experiencing fatigue or making mistakes due to human error. Secondly, they can significantly reduce production time, allowing manufacturers to meet increasing demands more efficiently. Lastly, automation eliminates the need for repetitive manual tasks, freeing up human workers to focus on more creative and complex aspects of garment production.

Narrative Style:

Imagine a world where sewing machines come to life, their robotic arms gracefully maneuvering through fabrics, creating intricate patterns with flawless precision. This is the reality that SoftWear Automation's engineers are bringing to the garment industry. Their industrial automation robots have the potential to transform the way we produce clothing, making it faster, more efficient, and ultimately more accessible to a global market.

As the garment industry continues to evolve, it's clear that industrial automation robots are leading the way towards a more efficient and sustainable future. With their ability to replicate the skills of human hands, these robots are poised to revolutionize the way we manufacture garments. So, buckle up and get ready for a new era in sewing, courtesy of industrial automation robots.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Link to the relevant manufacturer's website]. Industrial Robot

"Revolutionizing the Garment Industry: Unleashing the Power of Industrial Automation Robots"