Welcome to the world of automation and efficiency in secondary packaging! In this YouTube video, we will explore the incredible capabilities of the WinnTech PACK, a revolutionary Vertical Bagging Machine that is transforming the way products are loaded into various secondary containers. Whether you are in the food industry, pharmaceuticals, or any other sector requiring efficient packaging, this video is for you.

[Video Introduction]

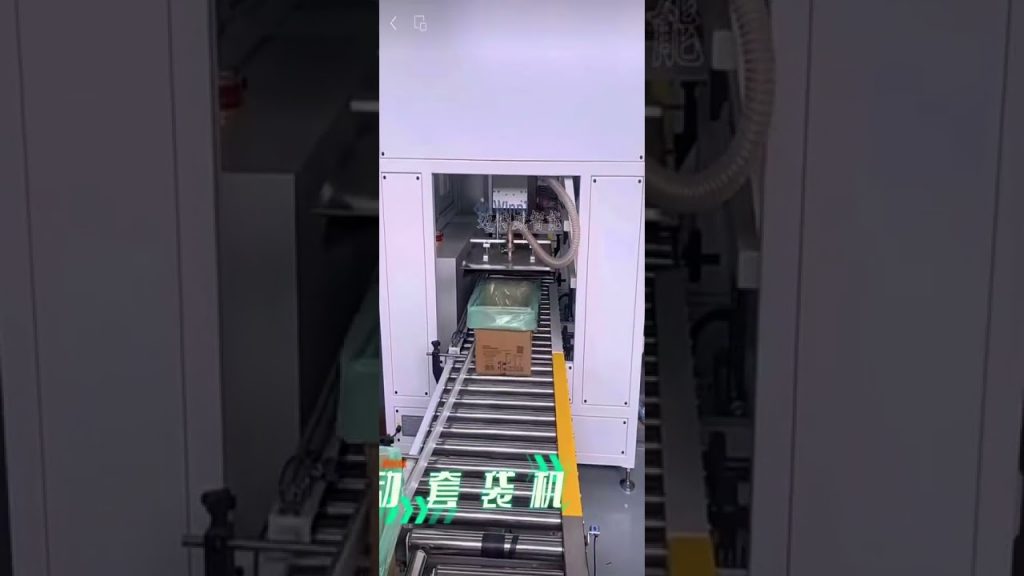

The WinnTech PACK is a game-changer in the field of secondary packaging automation. With its cutting-edge technology and advanced features, it has become the go-to solution for businesses seeking to streamline their packaging processes.

One of the standout features of the WinnTech PACK is its ability to handle a wide variety of products. From food items like snacks, grains, and candies to pharmaceutical products and household goods, this machine can efficiently load them into various secondary containers. This versatility makes it an ideal choice for businesses with diverse product ranges.

The Vertical Bagging Machine operates with precision and speed, ensuring that the packaging process is not only efficient but also accurate. The machine's intelligent sensors and controls guarantee that each product is properly loaded, minimizing wastage and ensuring consistent packaging quality.

But what sets the WinnTech PACK apart from other packaging machines is its integration with an Automatic Bagging Machine on Carton, Bag Top Sealing, and Vertical Pressing. This combination of technologies enables a seamless packaging process, from the initial bagging stage to the final sealing and pressing of the bags. The result is a perfectly packaged product that is ready for distribution.

[Video Demonstration]

Now let's dive deeper into the features and benefits of the WinnTech PACK.

1. Vertical Bagging Machine: This machine is designed to handle a wide range of products, including those that require careful handling, such as fragile items or those with irregular shapes. Its vertical loading mechanism ensures that each product is positioned correctly within the bag, minimizing the risk of damage during transportation.

2. Automatic Bagging Machine on Carton: The integration of the automatic bagging machine on a carton further enhances the efficiency of the packaging process. The machine automatically loads the bags onto cartons, eliminating the need for manual intervention and reducing the risk of human error.

3. Bag Top Sealing: The bag top sealing feature ensures that each bag is securely sealed, preventing any leakage or contamination. This is particularly crucial for food and pharmaceutical products, where product integrity and safety are of utmost importance.

4. Vertical Pressing: The final step in the packaging process is vertical pressing, which further enhances the stability and integrity of the packaged products. This ensures that the products are well-protected during transportation and storage.

In conclusion, the WinnTech PACK is a state-of-the-art solution for secondary packaging automation. Its ability to handle a variety of products, combined with its integration with an automatic bagging machine, bag top sealing, and vertical pressing, makes it a top choice for businesses seeking to optimize their packaging processes.

[Closing Remarks]

Thank you for watching this video about the WinnTech PACK and its incredible capabilities in secondary packaging automation. If you are looking for a reliable and efficient solution for your packaging needs, look no further. Check out the leading manufacturer for the professional solution right here:

[Link to the manufacturer's website] Bagging Machine

"Efficient Packaging Solutions: Streamline Your Operations with Advanced Bagging and Sealing Machines"