Welcome to our YouTube video on Small Plastic Injection Machines! In this article, we will provide you with an in-depth analysis of these machines and how they work. If you are looking for small business ideas or interested in hand molding machines, this video is perfect for you. So, let's dive in and explore the world of Small Plastic Injection Machines!

Introduction to Small Plastic Injection Machines:

Small Plastic Injection Machines are compact, versatile, and efficient machines used in the manufacturing industry. These machines play a crucial role in the production of plastic products, enabling businesses to create customized plastic parts with ease. Whether you are a small business owner or an individual interested in plastic manufacturing, understanding how these machines work can benefit you greatly.

Working of Hand Molding Machine:

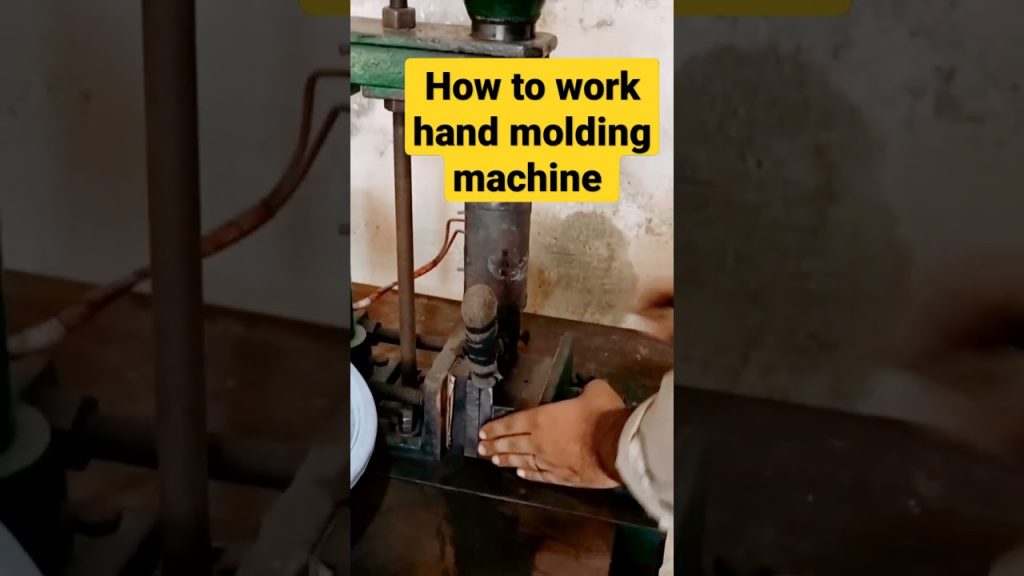

Hand molding machines are a type of Small Plastic Injection Machine that allows operators to manually control the injection process. These machines are popular among small-scale manufacturers and DIY enthusiasts who prefer a hands-on approach to plastic injection molding. By using a hand molding machine, operators can create plastic products according to their specific requirements, making it an ideal choice for those looking for a personalized touch.

Step-by-Step Guide to Using a Hand Molding Machine:

1. Preparation: Before using a hand molding machine, ensure that all necessary materials, molds, and safety equipment are readily available. It is crucial to follow proper safety protocols to minimize any potential risks.

2. Material Selection: Choose the appropriate plastic material depending on the desired characteristics of the final product. Different plastics have different melting points and properties, so selecting the right material is essential for successful injection molding.

3. Preparing the Mold: Clean and prepare the mold by removing any debris or residues. Apply a mold release agent if required to ensure easy removal of the final product.

4. Heating the Plastic: Place the plastic material in the machine's hopper and adjust the temperature settings accordingly. Heating the plastic resin to its melting point allows for easy flow during the injection process.

5. Injection Process: Once the plastic is melted, use the machine's manual control to inject the molten plastic into the mold. Apply consistent pressure and fill the mold completely to ensure accurate and high-quality results.

6. Cooling and Ejection: Allow the plastic to cool and solidify inside the mold. Once the plastic has cooled down, use the machine's ejection mechanism to remove the finished product from the mold.

7. Finishing Touches: Trim any excess plastic and perform any necessary post-processing steps, such as polishing or painting, to achieve the desired final product.

8. Quality Check: Inspect the final product for any defects or imperfections. Make adjustments to the process if needed to ensure consistent quality in future production runs.

By following these steps, operators can successfully utilize a hand molding machine to create a wide range of plastic products. The versatility and user-friendliness of these machines make them an excellent choice for small-scale plastic manufacturing.

Conclusion:

Small Plastic Injection Machines, particularly hand molding machines, are a valuable tool for small business owners and individuals interested in plastic manufacturing. Understanding the working principles and proper usage of these machines can help you unlock new business opportunities and create customized plastic products. Whether you are a DIY enthusiast or an aspiring entrepreneur, investing in a Small Plastic Injection Machine can be a game-changer for your business.

So, if you are ready to explore the world of plastic manufacturing with Small Plastic Injection Machines, check out our video for a detailed demonstration. Don't miss out on this exciting opportunity to enhance your business or unleash your creativity!

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert relevant call-to-action or link] Plastic Injection Machine

"Mastering Hand Molding Machines: Essential Guide for Small Business Owners Exploring Small Plastic Injection Machines"