Presentation on Industrial Robot Applications by Eric Nieves, Technology Director for Yaskawa Motoman Robotics USA at ROS-Industrial

In today's rapidly evolving industrial landscape, the role of robots in various applications has become increasingly important. One such technology that has gained significant attention is the Robot Operating System (ROS). To shed light on the potential of industrial robot applications and the importance of ROS for original equipment manufacturers (OEMs), Eric Nieves, Technology Director for Yaskawa Motoman Robotics USA, recently delivered a captivating presentation at the ROS-Industrial event.

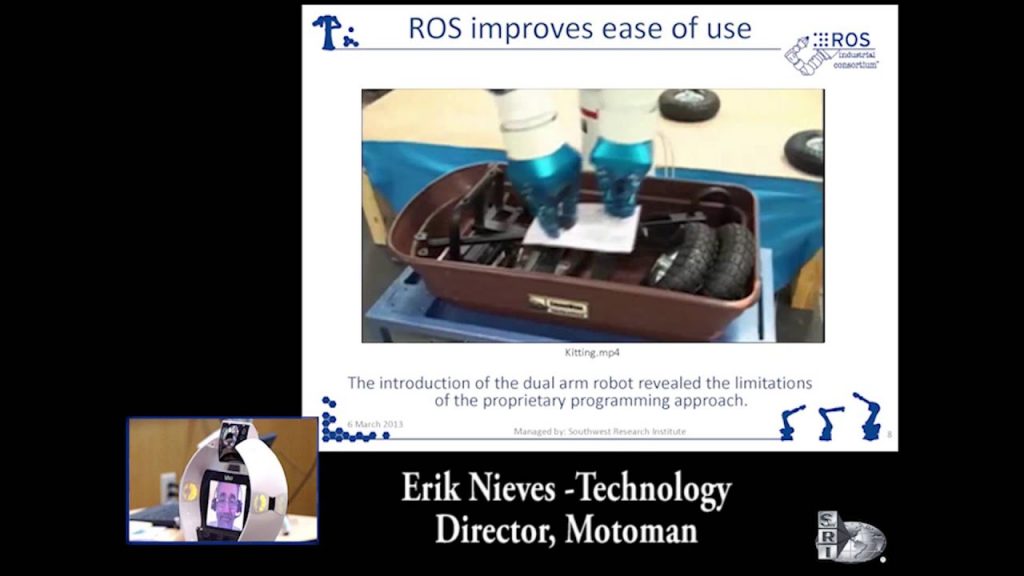

The presentation focused on the diverse range of industrial robot applications and how ROS can revolutionize the way OEMs approach robotics. Eric Nieves, with his extensive experience in the robotics industry, provided valuable insights into the potential of ROS and its impact on industrial automation.

Industrial Robot Applications: A World of Possibilities

Industrial robots have become an integral part of modern manufacturing processes. From assembly lines to material handling, these robots have proven their worth in enhancing productivity, efficiency, and precision. However, the potential of industrial robot applications extends far beyond these traditional use cases.

In his presentation, Eric Nieves explored various industrial robot applications that can benefit from ROS integration. He highlighted how ROS enables seamless communication and collaboration between robots, allowing them to work together efficiently. This opens up possibilities for complex tasks like coordinated assembly, autonomous navigation, and even human-robot collaboration.

Why Should Industrial Robot OEMs Care About ROS?

As the technology director for Yaskawa Motoman Robotics USA, Eric Nieves emphasized the significance of ROS for OEMs in his presentation. He highlighted how ROS provides a standardized and flexible framework for developing robot applications. This allows OEMs to focus on their core competencies without reinventing the wheel.

By adopting ROS, OEMs can leverage the vast open-source community and benefit from the collective knowledge and expertise. This not only reduces development time but also enables OEMs to deliver innovative and cost-effective solutions to their customers.

ROS also plays a crucial role in enhancing interoperability between different robotic systems. This enables seamless integration of robots from various manufacturers, creating a truly collaborative robotic ecosystem. OEMs can leverage this interoperability to expand their product offerings and cater to a wider range of applications.

The Future of Industrial Robot Applications with ROS

Eric Nieves' presentation also touched upon the future prospects of industrial robot applications with ROS. He highlighted how advancements in ROS and related technologies, such as artificial intelligence and machine learning, are shaping the next generation of industrial robotics.

With ROS, OEMs can develop intelligent robots capable of adaptive learning and decision-making. This opens up new avenues for automation in complex and dynamic environments. The ability of robots to learn from experience and optimize their performance will revolutionize industries such as logistics, healthcare, and agriculture.

Check the Industrial Robot Applications with Leading Manufacturers

If you are an OEM looking to explore the possibilities of industrial robot applications and harness the power of ROS, it is essential to partner with leading manufacturers who understand your unique requirements. They should have the expertise and experience to deliver tailored solutions that align with your business goals.

Leading manufacturers, with their in-depth knowledge of industrial robotics and ROS, can guide you through the process of integrating ROS into your products. They can provide you with the necessary hardware, software, and support to ensure a seamless and successful implementation.

In conclusion, Eric Nieves' presentation on industrial robot applications and the significance of ROS shed light on the immense potential of this technology. By embracing ROS, OEMs can unlock a world of possibilities and stay ahead in the ever-evolving industrial landscape. So, if you're an OEM looking to explore industrial robot applications, partnering with leading manufacturers is the key to success.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [insert manufacturer's website link] Industrial Robot

"Unlocking the Potential: The Importance of ROS in Industrial Robot Applications for OEMs"