Looking for a reliable labeling machine for your tin products? Look no further! In this article, we will explore the fascinating world of tin labeling machines and how they work. Whether you are a manufacturer, distributor, or simply curious about the labeling process, this article will provide you with valuable insights. So, let's dive in!

Labeling machines have revolutionized the packaging industry by automating the labeling process. These machines are designed to apply labels onto various types of products, including tin cans and bottles. With their high efficiency and accuracy, they have become an essential tool for businesses in the food, beverage, and cosmetics industries.

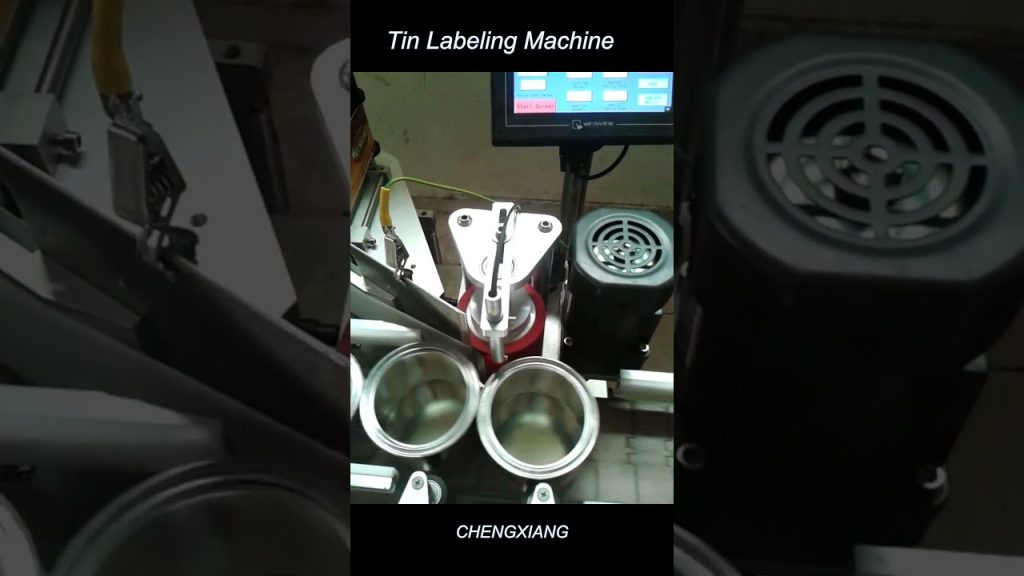

So, how does a sticker labeling machine work? Let's break it down step by step:

1. Product Placement: The first step is to ensure that the tin cans or bottles are properly placed on the conveyor belt of the labeling machine. This can be done manually or through an automated feeding system.

2. Label Dispensing: Once the products are in position, the labeling machine's label dispensing system comes into play. The machine is equipped with a roll of labels that are fed into the system. The labels are then separated and dispensed onto a labeling head.

3. Labeling Process: As the products move along the conveyor belt, the labeling head applies the labels onto the tin cans or bottles. The labeling head uses a combination of pressure and adhesive to ensure that the labels adhere firmly to the surface of the products. The labeling machine is designed to apply labels accurately and consistently, even at high speeds.

4. Inspection and Verification: After the labeling process, the labeled products pass through an inspection system. This system checks for any misaligned or missing labels. If any issues are detected, the products are rejected or diverted for manual inspection and correction.

5. End of Line Packaging: Once the labeling process is complete, the tin cans or bottles are ready for the next stage of packaging, such as capping, sealing, or shrink wrapping. The labeled products are then prepared for distribution or display.

Labeling machines offer several benefits to businesses. Firstly, they improve efficiency by automating the labeling process, reducing the need for manual labor. This results in cost savings and increased productivity. Secondly, these machines ensure accuracy and consistency in label application, enhancing the visual appeal of the products. Lastly, labeling machines can handle a wide variety of label sizes and shapes, making them versatile for different packaging requirements.

In conclusion, the labeling machine is a game-changer in the packaging industry. Its ability to automate the labeling process, improve efficiency, and ensure accuracy makes it an invaluable tool for businesses. Whether you are labeling tin cans, bottles, or any other product, investing in a high-quality labeling machine will undoubtedly streamline your operations and boost your brand's image.

So, if you're in the market for a labeling machine, look no further! Check out our range of labeling machines today and take your packaging process to the next level.

Check the labeling machine solutions with leading manufacturers for professional solutions, right here! Labeling Machine

"Efficient and Precise Tin Labeling Machine: Unveiling the Inner Workings of Sticker Labeling Technology"