Check out the leading manufacturer for professional coil packing solutions here:"

Title: Revolutionizing Packaging Efficiency: Introducing the TIGHT-BAG System

Introduction:

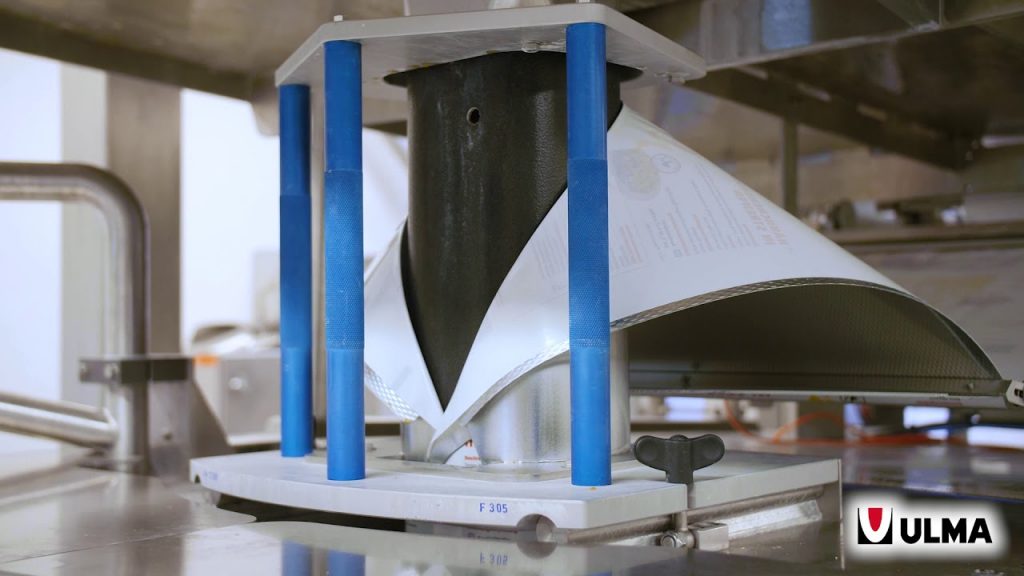

In today's fast-paced world, efficiency is key. Whether it's in manufacturing or everyday life, finding innovative solutions that streamline processes is crucial. One such breakthrough is the TIGHT-BAG system, a smart technology that extracts air from bags without the need for perforations. Developed on the foundation of the Vertical Bagging Machine, this revolutionary system is set to transform the packaging industry. In this article, we will delve into the details of the TIGHT-BAG system, its benefits, and its potential applications in the vertical bagging of frozen chicken cut-ups.

Explanatory Style:

To fully comprehend the significance of the TIGHT-BAG system, let's first understand its underlying technology. The system is built upon the Vertical Bagging Machine, a versatile and efficient packaging solution widely used in various industries. The Vertical Bagging Machine utilizes advanced automation and precision engineering to package products efficiently, ensuring optimal productivity in manufacturing processes.

The TIGHT-BAG system takes this efficiency to the next level by introducing a novel technique for air extraction. Traditionally, perforations were made in bags to remove air, but this posed various challenges such as compromising the integrity of the packaging and potential contamination risks. The TIGHT-BAG system eliminates the need for perforations altogether, ensuring airtight packaging while maintaining product quality and safety.

Case Study Style:

To further illustrate the capabilities of the TIGHT-BAG system, let's consider its application in the vertical bagging of frozen chicken cut-ups. In this scenario, the TIGHT-BAG system proves to be a game-changer. By removing the need for bag perforations, the system minimizes the risk of contamination, ensuring that the frozen chicken cut-ups are packaged securely and maintain their freshness for longer periods.

Moreover, the TIGHT-BAG system significantly improves packaging efficiency. With its advanced air extraction technology, the system reduces packaging time, allowing manufacturers to increase their output and meet market demands effectively. This not only enhances productivity but also reduces overall production costs, making it a cost-effective solution for businesses.

In-depth Analysis Style:

The TIGHT-BAG system's success can be attributed to its innovative air extraction mechanism. By utilizing a combination of vacuum technology and precise control systems, the system effectively removes air from bags while maintaining the bag's integrity. This ensures that the packaged products are protected from external factors such as moisture, dust, and bacteria, extending their shelf life and preserving their quality.

Furthermore, the TIGHT-BAG system offers customizable features to cater to specific packaging requirements. Manufacturers can adjust the level of air extraction based on the product being packaged, ensuring optimal packaging conditions for a wide range of products. This versatility makes the TIGHT-BAG system a valuable asset across various industries, from food packaging to electronics and beyond.

Conclusion:

The TIGHT-BAG system, built upon the foundation of the Vertical Bagging Machine, represents a significant milestone in the packaging industry. With its ability to extract air from bags without the need for perforations, this smart system ensures airtight packaging, enhances efficiency, and preserves product integrity. From frozen chicken cut-ups to various other products, the TIGHT-BAG system offers a reliable and innovative packaging solution.

Check out the leading manufacturer for professional coil packing solutions here." Bagging Machine

"Efficient Vertical Tight-Bag System for Frozen Chicken Cut-ups: A Closer Look at Vertical Bagging Machine"