A pallet stretch wrapping machine is an essential piece of equipment for any warehouse or distribution center. Its purpose is to wrap stretch film around a pallet of goods in a fast and efficient manner, securing the items for transportation or storage. There are several advantages to using a pallet stretch wrapping machine, including:

- Protection of goods: The wrapping of plastic film around the pallet helps to protect the items from damage during handling, transportation, and storage. The film acts as a barrier against scratches, dust, and moisture, ensuring that the goods remain in good condition.

- Reduction of theft and loss: By wrapping the pallet securely, the stretch wrapping process reduces the risk of theft and loss of goods during transportation. The tight wrapping makes it difficult for thieves to tamper with the contents of the pallet, minimizing the risk of theft and loss.

- Stabilization of goods: Stretch wrapping helps to stabilize the goods on the pallet, reducing the risk of damage during transit. This is especially important for fragile or heavy items, as it reduces the risk of them shifting or falling off the pallet.

- Improved stacking: The tight wrapping of the stretch film helps to improve stacking, making it easier to store and transport multiple pallets of goods. The wrapping holds the goods in place, reducing the risk of damage and ensuring stability during stacking.

There are several types of pallet stretch wrapping machines, including manual, semi-automatic, and fully automatic models.

Manual pallet stretch wrapping machines are the simplest type of machines and require manual operation. They are typically the most affordable option and are suitable for operations with lower volumes of goods.

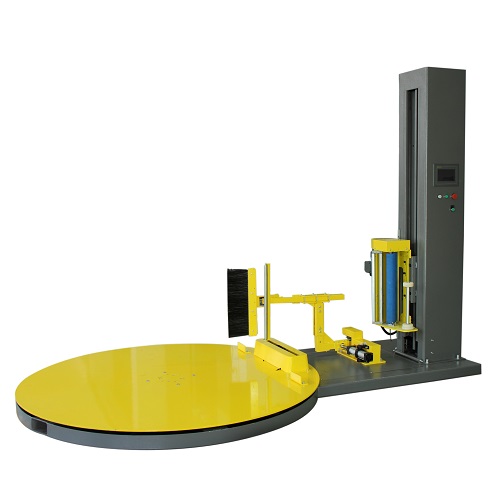

Semi-automatic pallet stretch wrapping machines automate part of the wrapping process, usually the application of the stretch film. This type of machine is suitable for operations with a higher level of automation but do not require the full automation of a fully automatic machine.

Fully automatic pallet stretch wrapping machines automate all aspects of the wrapping process, including the application of the stretch film, the wrapping of the pallet, and the cutting of the film. These machines are ideal for high-volume operations and provide the highest level of efficiency and automation.

When choosing a pallet stretch wrapping machine, it is important to consider several factors, including the volume of goods to be wrapped, the size and weight of the pallets, and the speed and efficiency required. Other factors to consider include the level of automation needed, the size and space available for the machine, and the budget available.

In conclusion, a pallet stretch wrapping machine is a valuable investment for any operation that requires the secure transportation or storage of goods. The machine helps to protect the goods, reduce the risk of theft and loss, stabilize the goods during transit, and improve stacking. With a range of manual, semi-automatic, and fully automatic models available, there is a stretch wrapping machine to meet the needs of every operation.

Choosing a pallet stretch wrapping machine can be a challenge, but by keeping a few key factors in mind, you can select the right machine for your needs. Here are the most important things to consider when choosing a pallet stretch wrapper:

- Load size and weight: Consider the size and weight of your pallets, as well as the dimensions of the loads you will be wrapping. Make sure the machine you choose is capable of handling your load size and weight.

- Speed: The speed at which a machine can wrap a pallet is an important factor to consider. Determine the ideal speed for your operation and choose a machine that can meet those requirements.

- Wrapping style: There are several different wrapping styles to choose from, including turntable, orbital, and rotary arm. Determine the best wrapping style for your operation based on the size and weight of your loads, and choose a machine that can accommodate that style.

- Film type and size: Consider the type of film you will be using and make sure the machine you choose is compatible with that film type. You should also consider the size of the film rolls and make sure the machine has sufficient space to store them.

- Film dispensing: Consider the type of film dispensing system you prefer, such as manual, semi-automatic, or automatic. Choose a machine that can accommodate your preferred dispensing system.

- Film tension control: Film tension is a critical factor in the wrapping process. Choose a machine that has a good film tension control system to ensure consistent and reliable wrapping results.

- Safety features: Safety should always be a top priority when choosing a pallet stretch wrapping machine. Look for machines with safety features such as emergency stop buttons, safety guards, and automatic shut-off systems.

- Ease of use: Make sure the machine you choose is easy to operate, maintain, and repair. Consider features such as user-friendly controls and easy access to the film dispensing system.

- Warranty: Consider the warranty offered by the manufacturer and make sure it covers any potential issues you may encounter with the machine.

- Price: Price is always a factor to consider when choosing a pallet stretch wrapping machine. Determine your budget and choose a machine that offers the features you need at a price that fits within your budget.

By considering these key factors, you can select the right pallet stretch wrapping machine for your needs. Take the time to research different options, compare features and prices, and choose a machine that is best suited for your operation. With the right machine, you can ensure that your pallets are properly wrapped, protected, and ready for shipment.